Airlines today face a simple yet urgent expectation from digital-Smart factory solutions are redefining how manufacturers compete in the digital era. Instead of relying on isolated automation, modern factories integrate data, software, and intelligent execution systems to create connected, adaptive production environments.

According to Global Market Insights, the global smart factory market is expected to grow from USD 110 billion in 2022 to USD 280 billion by 2032, with a CAGR above 9%

Despite this growth, many manufacturing leaders still ask the same questions:

- What tangible business value do smart factory solutions deliver?

- How do MES, cloud MES software, and automation work together?

- Which approach delivers ROI without disrupting operations?

This guide provides a practical, execution-focused view of smart factory solutions, with a strong focus on smart MES, cloud-based manufacturing execution systems, and real-world use cases.

What is a Smart Factory?

A smart factory utilizes advanced digital technologies to automate, link and optimize the way manufacturing processes happen. Smart factory solutions provide tools for allowing companies to have a more integrated approach to manufacturing, with less reliance on manual inputs while increasing speed, productivity and cost efficiency. Smart factory is a key component of digital transformation of manufacturing enterprises.

Using the Industrial Internet of Things (IIoT) and cyber-physical systems, a smart factory connects the actual factory floor with digital systems at the operations level. Info from machines, sensors, and logistics goes into central platforms (often powered by smart MES). This gives a real-time view of production, improves coordination, and allows for performance monitoring.

| Aspect | Traditional Factory | Smart Factory Solutions |

| Data flow | Manual, siloed | Real-time, integrated |

| Execution | Operator-dependent | MES automation |

| Visibility | Limited | End-to-end |

| Scalability | Low | Cloud-enabled |

| Decision-making | Reactive | Data-driven |

Smart Factory vs Traditional Factory

From a company standpoint, smart factories have tangible results. They enable manufacturers to respond more flexibly to evolving consumer demands, maximize labor and energy, shorten production and delivery cycles, design a more appealing and contemporary workplace, and automate logistical activities from order placement through final delivery.

Key components of Smart Factory Solutions

Smart factory solutions rely on multiple technologies working together as a single, connected system. Rather than operating independently, each component continuously exchanges data to enable automation, visibility, and optimization.

The core elements upon which intelligent manufacturing systems are built are shown in the table below:

| Component | Description |

| Industrial internet of things (IIoT) | Connects machines and sensors for real-time data collection and machine-to-machine communication |

| Big data, AI, and analytics | Supports predictive maintenance, quality inspection, and process optimization |

| Messaging protocols | Protocols such as MQTT and AMQP guarantee dependable and safe communication among devices. For important operations, they help guarantee message delivery as well as lightweight sensor communication. |

| Robotics and automation | Executes repetitive tasks with high accuracy and consistency |

| Cloud MES software | Enables scalability, centralized control, and remote access across sites |

| Digital twins | Create virtual models of machines or factories for simulation and optimization |

Key smart factory components

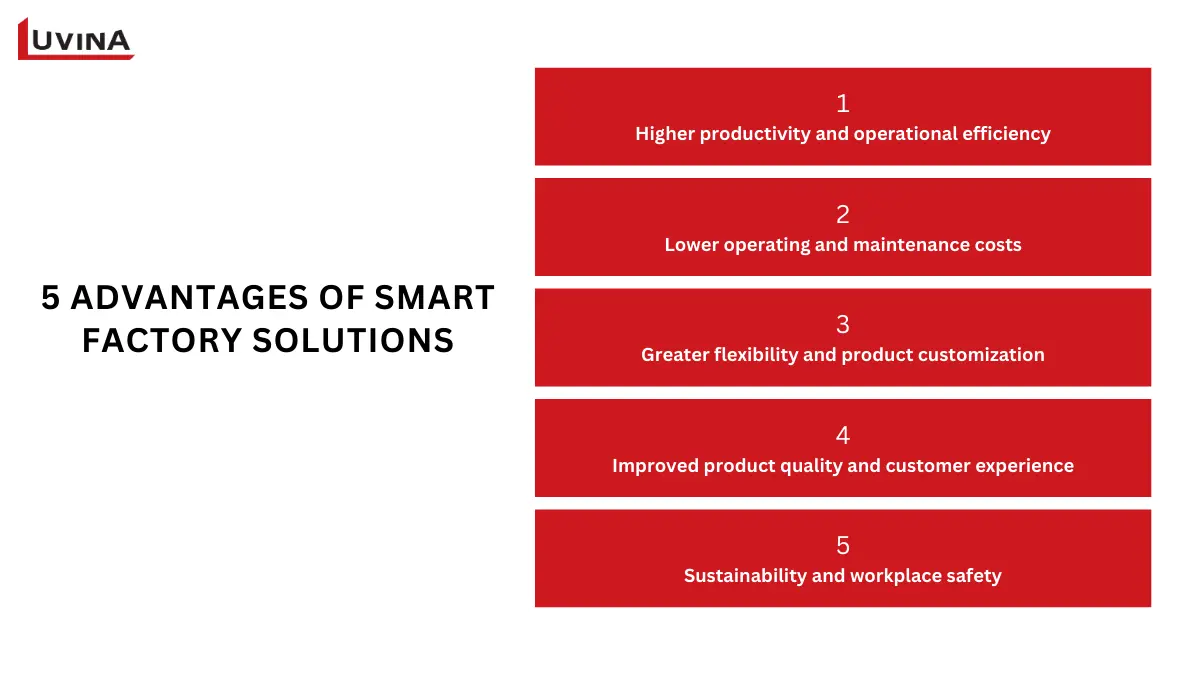

Benefits of Smart Factory Solutions

Beyond their technological improvement, smart factory solutions generate clear commercial value by enhancing factory operation, reaction, and scale. The advantages listed explain why intelligent factories are becoming more and more a strategic focus rather than a distant dream.

In the digital era, smart factory solutions deliver a wide range of benefits

Higher productivity and operational efficiency

Automation, artificial intelligence, and predictive analytics enable to maximization of production flows, minimize unexpected downtime, and lower human mistakes. Deloitte claims that smart factory programs have resulted in manufacturing output, factory use, and labor productivity up to 12% improvement. Smart factories are predicted to produce 30% more net labor productivity than conventional plants by 2030.

Lower operating and maintenance costs

With real-time monitoring and predictive maintenance, you can spot problems early – before anything breaks down. Over time, smart factory solutions save money. They cut repair bills, make it faster to plan maintenance, and help you avoid those unexpected breakdowns that throw everything off.

Greater flexibility and product customization

Connected systems let producers swiftly adapt to fluctuating demand and personalize goods without having to alter whole production lines by means of fast changes to production processes.

Improved product quality and customer experience

Early defect detection and consistent standards are guaranteed by constant, real-time quality monitoring. Often supported by a cloud-based manufacturing execution system, end-to-end visibility helps to better coordinate the supply chain, hence reducing returns, recalls and increasing client happiness.

Sustainability and workplace safety

Smart factories are designed to efficiently use energy, reduce waste from material consumption, and enable environmentally friendly manufacturing processes. Additionally, since automation and robotics can assist in the reduction of the number of injuries associated with workplace accidents, these technologies enhance the safety of workers as well as promote sustainability within an organisation’s operational activities through the implementation of smart factory solutions.

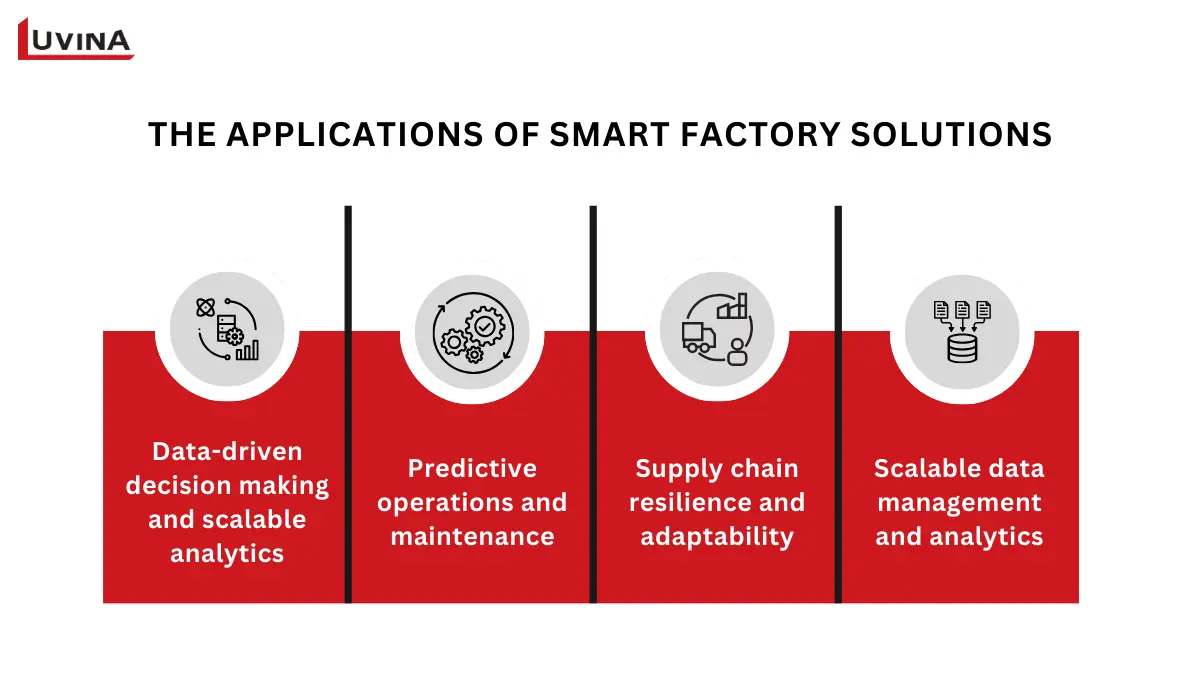

Use-cases & Industry Examples

Smart factory solutions go from idea to real operational influence here. Across sectors, manufacturers are utilizing data, connectivity, and automation to address daily production problems. Common applications include:

Some common use cases of smart factory technologies

Predictive operations and maintenance

Still dependent on reactive reactions when issues arise, many manufacturers treat symptoms rather than root causes. Combining real-time data and analytics, smart factory solutions let one take a predictive approach to grasp present conditions and foresee future risks. Then decisions on maintenance, production, and quality are guided by exact insights instead of by need.

Using predictive analytics and big data to foresee maintenance requirements, minimize downtime, and maximize workflows, GE’s Brilliant Factory model is a clear illustration of this strategy. This capacity to predict has allowed operational efficiency to be enhanced and maintenance-related expenses to be reduced.

Supply chain resilience and adaptability

Although mostly unavoidable, supply chain instability may be controlled. Using smart factory solutions, producers get improved visibility into material flow, production capacity, and inventory. Data and automation give teams the freedom to react to outside shocks by letting them concentrate on what they can influence.

BMW’s Smart Factory in Regensburg demonstrates how quickly vehicle modification is made possible without stalling assembly lines by means of digital twins, cooperative robots, and AI-based scheduling. This enables the plant to manage great product variation while preserving constant quality and efficient resource use.

Data-driven decision making and scalable analytics

Data-driven decision making and scalable analytics are only effective when manufacturing data is unified and easy to act on. Smart factory solutions create a centralized data environment where information from machines, people, and systems is collected, analyzed, and translated into consistent, insight-driven decisions across plants and production lines.

A clear example is Siemens Electronics Works in Amberg, Germany, where an IoT-connected digital ecosystem, AI-driven quality control, and real-time process monitoring enable the factory to produce millions of electronic devices each year with near-zero defects.

As factories scale, smart factory solutions also replace fragmented tools with automated data collection and real-time analytics. At Bosch Rexroth’s Homburg plant, more than 200 connected machines support highly flexible production of hydraulic valves while maintaining short lead times.

On top of this foundation, platforms such as MES SaaS allow manufacturers to track performance, compare metrics across lines, and continuously improve by turning raw production data into practical operational insights.

Condition-based and proactive maintenance

Conventional maintenance methods frequently delay action until equipment fails, resulting in expensive downtime. Smart factory solutions use condition-based monitoring to spot early wear or aberrant behavior. At the appropriate moment, maintenance teams can step in to avoid failures and plan repairs around production timelines.

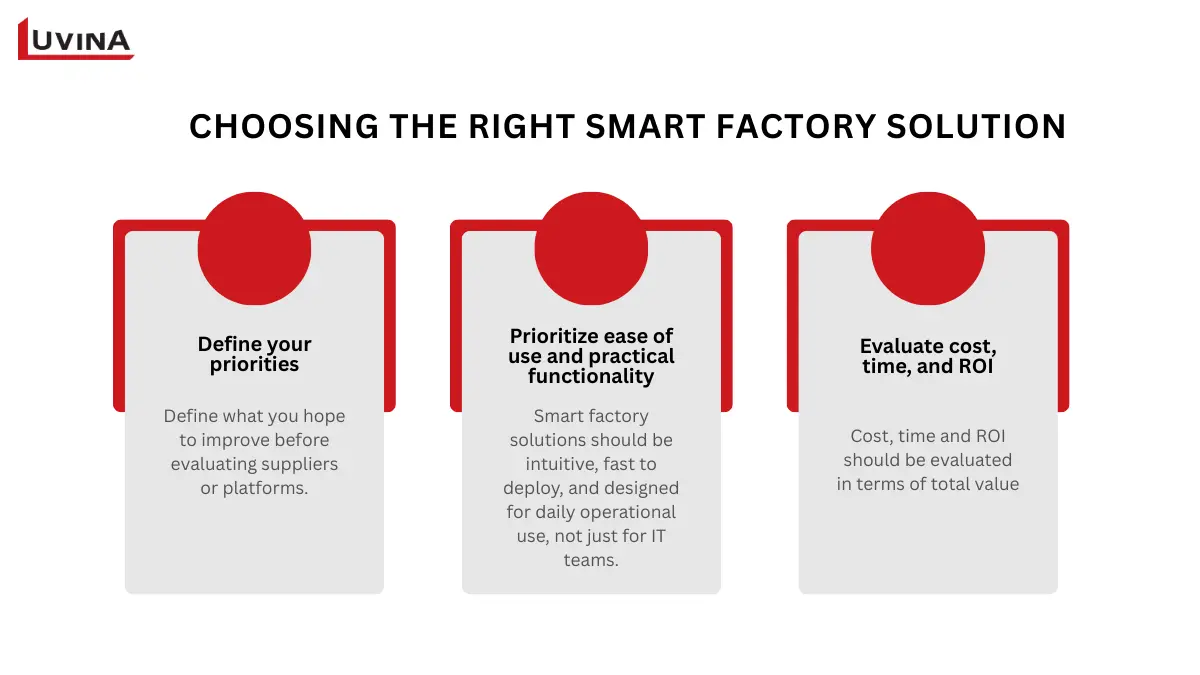

How to choose the right smart factory solution for your plan?

The process by which a manufacturer selects their smart factory solutions is a business decision that impacts their ability to be productive, control costs, and grow their business over time. Instead of concentrating on technology, manufacturers need to look at solutions and evaluate those solutions based on how they align with their business objectives, the ease of use, and the return on investment that is quantifiable.

3 key considerations to help you choose the most suitable solution

Define your business and operational priorities

Define what you hope to improve before evaluating suppliers or platforms. The most successful smart factory solutions are those in line with particular operational objectives, including:

– Reducing unplanned downtime

– Improving product quality

– Increasing production output

– Gaining real-time visibility to support faster, data-driven operations management

– Understanding capacity constraints

Clearly stated goals guide one toward solutions that provide value rapidly rather than introduce needless complexity.

Prioritize ease of use and practical functionality

Adoption on the shop floor is critical. Smart factory solutions should be intuitive, fast to deploy, and designed for daily operational use, not just for IT teams. Key aspects to evaluate include: real-time dashboards and visual KPIs, an all-in-one system, scalability, mobile access, compatibility, flexibility,…

A system that operators and managers actually use will always outperform a more complex solution that remains underutilized.

Evaluate cost, time, and return on investment

Cost should be evaluated in terms of total value, not just software price. Compare smart factory solutions using:

– Implementation time and how quickly the system can go live

– Internal IT effort required to deploy and maintain the solution

– Training time needed for operators and managers

– The speed at which measurable benefits

Often postponing ROI, solutions that take months or years to install can be contrasted with configurable platforms that start providing value in weeks. The correct decision balances speed, long-term effect, and budget.

Different manufacturers adopt MES in different ways depending on scale, regulation, and speed requirements. Choosing the right smart factory solution that best fits your needs is a must in any plan.

| MES Model | Description | Best Fit |

| On-prem MES | Installed locally | Highly regulated industries |

| Cloud-based MES | Hosted on cloud infrastructure | Multi-site enterprises |

| MES SaaS | Subscription-based, fast deployment | SMEs and fast-scaling factories |

MES Deployment Models in Smart Factories

Challenges and common pitfalls when deploying Smart Factory

The deployment of smart factory solutions in real-world factories is most often not easy, despite the significant potential benefits that these technologies offer manufacturers in terms of efficiency, quality, and flexibility. Understanding the common pitfalls of deploying connected factory platforms will provide manufacturers with more realistic expectations of how to deploy these technologies within their factories at a greater scale and lower the risks associated with the deployment of smart factory solutions.

The following are some of the most common challenges faced by manufacturers and proposed solutions for overcoming these challenges.

| Challenge | What it means | How to address |

| High initial investment costs | High upfront costs for digital infrastructure, automation, and system integration. | Start with priority use cases and scale smart factory solutions based on proven ROI. |

| Integration with legacy systems | Older machines, ERP systems, and legacy software are difficult to connect to modern platforms. | Use modular solutions and phased deployment to minimize disruption. |

| Skills gap and workforce readiness | Employees lack digital and data-related capabilities. | Provide focused training and user-friendly tools such as smart mes. |

| Data overload without insight | Large data volumes without a clear direction reduce decision quality. | Define KPIs early and align smart factory solutions to business goals. |

| Data security and privacy risks | Higher connectivity increases exposure to cyber threats. | Apply strong security standards, access control, and regular updates. |

| Lack of ownership and governance | Unclear responsibility leads to stalled initiatives. | Assign clear ownership across IT and operations teams. |

Common challenges and solutions for smart factories

Smart Factory trends shaping modern manufacturing

Modern industrial policies centre on smart factories. Therefore, they are more and more based on scalable digital systems that mix data, automation, and smart decision-making to maintain long-run competitiveness.

The key trends that will impact the development of smart factory solutions into the future are as follows:

– 5G integration: 5G will provide ultra-fast, low-latency connections between machines and sensors with control systems so that they can communicate and share data in real-time.

– Edge AI for real-time decision-making: Smart factory solutions utilize edge AI by placing it on the production floor so that production anomalies are detected, processes are immediately corrected and reliance on cloud-based processing is reduced.

– Blockchain-enabled supply chain visibility: The combination of using blockchain within the supply chain enhances the ability of companies to share accurate, secure and tabulated data through the supply chain to end-users.

– Sustainable and energy-efficient: Incorporating advanced analytics and monitoring systems into the supply chain allows manufacturers to decrease waste during the manufacturing process, effectively use energy within the manufacturing process and implement smart factory solutions that comply with both sustainability and compliance regulations.

– Human-centric automation: Combining cobots, AI-enhanced technologies and cloud MES software enhances the safety of workers, improves the quality of decisions made in production, and maintains the balance between human expertise and automation.

Conclusion

Smart factory solutions are no longer optional. They are becoming the foundation of manufacturing competitiveness.

By combining smart MES, cloud-based manufacturing execution systems, MES automation, and data-driven decision-making, manufacturers can achieve higher productivity, better quality, and long-term operational resilience.

Building a smart factory is a continuous journey. With clear goals, scalable technology, and the right execution partner, it becomes a sustainable engine for growth.

Luvina supports manufacturers in translating smart factory strategies into measurable business outcomes through tailored consulting and implementation.

Resources

- https://www.sap.com/products/scm/what-is-a-smart-factory.html

- https://www.emqx.com/en/blog/what-is-a-smart-factory-key-components-4-levels-of-evolution#key-components-of-a-smart-factory

- https://www.plantengineering.com/five-smart-factory-use-cases-and-why-they-matter/

- https://www.linkedin.com/pulse/smart-factory-solutions-market-ai-adoption-trends-2025-z1jyf/

- https://www.e-spincorp.com/a-smart-factory-elements-benefits-trends/

- https://www.mingosmartfactory.com/how-to-choose-the-right-smart-factory-system/

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter