Manufacturers already get the value of MES. Choosing the best MES software that fits their operations, teams, and long-range objectives is now the actual difficulty, as choices seem comparable and marketing statements are similar.

This guide is written for manufacturing leaders who already understand what MES is, but are struggling to choose the right system among many similar-looking options. Instead of ranking vendors by popularity, this article focuses on decision criteria, deployment fit, and real-world trade-offs to help you select an MES that actually works on your shop floor.

What is MES software?

A Manufacturing Execution System (MES) is a computer-based system that “manages, monitors and synchronizes the execution of real-time, physical processes involved in transforming raw materials into intermediate and/or finished goods.” (Gartner).

MES software plays a critical role in modern manufacturing by supporting the following operational goals:

- Turns raw production data into actionable insights, helping manufacturers optimize productivity, cost, and quality using the best MES software.

- Provides end-to-end visibility from order release to finished goods, enabling faster and more accurate decision-making.

- Supports regulatory compliance, traceability, and consistent product quality while improving responsiveness to changing market demands.

Criteria for comparison

For an effective evaluation of MES platforms, manufacturers require a well-defined and consistent set of criteria that accurately reflects their current production requirements. The list below concentrates on some key criteria used to evaluate functionality, usability, scalability, and reliability over time. The purpose of it is to assist with selecting the best MES software solution for various types of manufacturing operations and/or goals.

| Criteria | Description | |

| Core execution capability | Core functionality and real-time visibility | The best MES software should deliver key execution functions while providing real-time visibility into production performance, quality, and shop-floor status for faster decision-making. |

| Ease of use and adoption | User-friendly interfaces, simple workflows, and low training effort. | |

| Customization control | Flexible yet manageable customization allows the MES production software to adapt to different plant requirements without increasing complexity. | |

| Vendor and long-term risk | Licensing transparency | Clear licensing models with no hidden costs are important when comparing the best MES software. |

| Vendor maturity and system fit | When choosing the best MES software, proven vendor support and customer references should be evaluated alongside clear system limitations to ensure realistic expectations and proper fit. | |

| Integration and scalability | Integration capabilities | Seamless integration with ERP, QMS, inventory systems, and shop-floor equipment is a key requirement. |

| Standards and protocols | Support for common industrial standards and APIs ensures long-term interoperability across top MES systems. | |

| Scalability and flexibility | The best MES software must scale easily as production volume, automation level, and process complexity increase. | |

| Multi-language and time-zone support | Global-ready best manufacturing software supports centralized updates and consistent user experiences across locations. | |

| Deployment and lifecycle | Deployment lifecycle and platform stability | A reliable MES supports smooth rollout across plants and maintains long-term stability through controlled upgrades, minimal downtime, and rollback capabilities. |

| Infrastructure requirements | Evaluating hardware and system demands ensures the best MES software performs reliably within existing IT environments. |

Key criteria for comparing and selecting an MES system

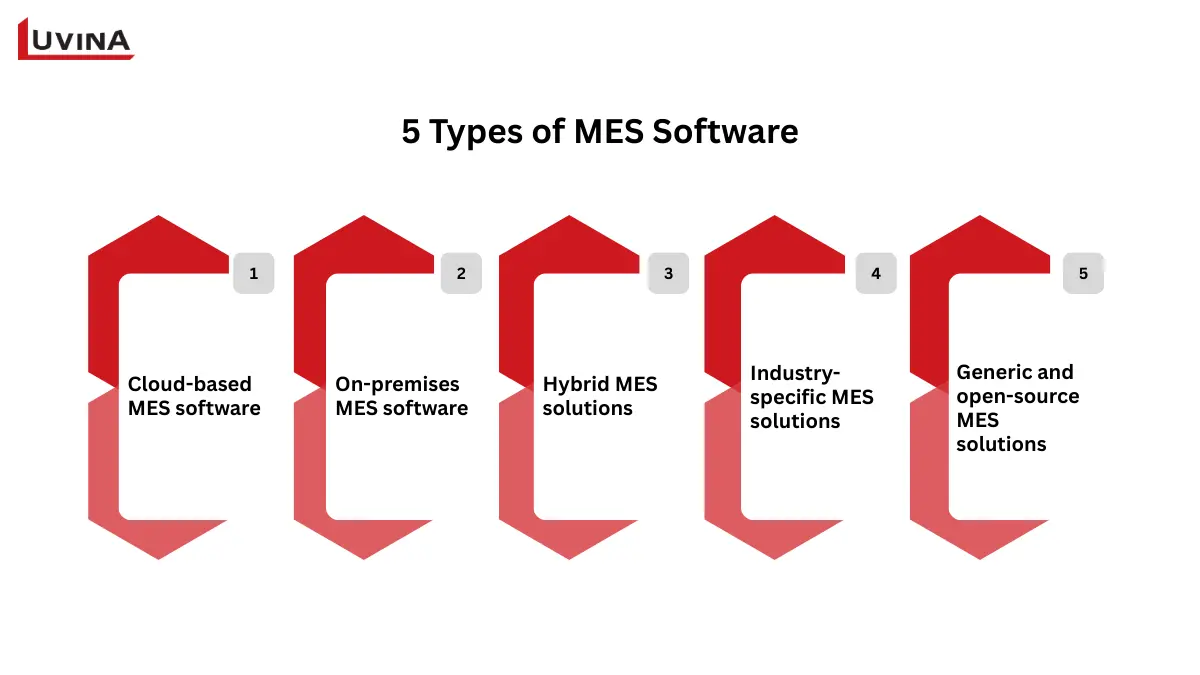

Types of MES Software in Today’s Market

Understanding the major categories of MES and how each one addresses different manufacturing requirements is the first step in selecting the ideal MES. From flexible cloud solutions to highly regulated on-premises systems and bespoke industry solutions, today’s market presents a wide spectrum of possibilities. Knowing these distinctions helps producers choose the best MES software depending on deployment preferences, compliance needs, and long-term operational targets.

Current MES software today mainly falls into one of these 5 types

Cloud-based MES software

Available from anywhere with an internet connection, cloud-based MES software is a type of best MES software that operates on remote servers. Third-party providers handle these systems, hence lowering on-site infrastructure and IT upkeep requirements. Many producers view cloud solutions as an appealing gateway to digital manufacturing because of quicker deployment and cheaper initial cost.

Real-time data access across many facilities is made possible by this kind of MES, therefore facilitating large-scale production performance monitoring. Automatic updates and subscription-based pricing also enable manufacturers to keep current without difficult upgrade cycles. Cloud solutions are sometimes regarded as among the best MES software choices now available for companies looking for speed and flexibility.

– Best fit for: Organizations prioritizing rapid deployment, lower upfront investment, and multi-site visibility.

– Less suitable for: Environments with strict data residency, compliance, or offline-first requirements.

On-premises MES software

With total control over data, security, and system setup, on-premises MES software is installed and run within a company’s own infrastructure. For producers in very controlled sectors or those with rigorous internal IT policies, this strategy fits ideally.

Deep personalization of on-premises systems lets you fit particular workflows, equipment, and compliance requirements. Less reliant on internet access, they guarantee continuous operations in settings where network stability is especially important. Though the first cost is more, on-premises systems continue to be a great choice for businesses assessing the best MES software with long-term control in mind.

– Best fit for: Manufacturers needing full data control, deep customization, and high regulatory compliance.

– Less suitable for: Teams seeking quick rollout, minimal IT overhead, or elastic scalability.

Hybrid MES solutions

Manufacturers can use both the cloud and on-premise capabilities of hybrid product feature MES solutions to maintain sensitive information on their premises while using the cloud for analytics, reporting, and remote access. Among the best MES software, hybrid solutions allow for flexibility and control, which is beneficial to manufacturers in managing complex or regulated operations.

Hybrid systems are often adopted by manufacturers transitioning gradually to cloud technologies. They offer scalability without forcing a full infrastructure overhaul, making them a practical option within many top manufacturing execution systems used today.

– Best fit for: Operations requiring both on-site control and cloud-level analytics or phased cloud adoption.

– Less suitable for: Simple IT landscapes where architectural complexity adds limited value.

Industry-specific MES solutions

Specific best MES softwares are tailored to the exact requirements of each sector (automotive, pharmaceutical, food and beverage, etc.). Each industry-specific MES solution provides industry-specific preconfigurations such as workflow requirements, regulatory compliance functionality, reporting formats, etc.

By lowering the demand for significant customization, industry-focused platforms expedite implementation time and reduce deployment risk.

– Best fit for: Regulated industries with standardized processes and compliance-driven workflows.

– Less suitable for: Highly customized or cross-industry manufacturing environments.

Generic and open-source MES solutions

Generic best MES software is designed to support multiple industries and types of manufacturing. They address primary MES functions, including manufacturing scheduling, status tracking, and resource management; however, because these features can be customized for each manufacturer’s unique operational requirements, they are flexible enough to meet the needs of manufacturers using many different or changing process models.

In addition, some manufacturers explore MES manufacturing execution system open source options to gain more control over system architecture and development. Open-source MES solutions appeal to organizations with strong internal technical capabilities, offering adaptability and cost advantages while requiring greater responsibility for maintenance and support.

– Best fit for: Organizations with strong in-house technical capabilities and a need for flexibility.

– Less suitable for: Companies expecting turnkey deployment, vendor-led support, or minimal customization.

10 Best MES Software

In this section, we will highlight 11 widely adopted solutions that represent different approaches to manufacturing execution. Before deep diving into the introduction of each software, the overview table below gives you a high-level snapshot of how each option fits into the broader best mes software landscape.

This manufacturing execution system software list is organized by deployment model and primary use case, making it easier to identify which solutions align with your production scale.

| Type of software | Software | Key features | Best fit |

| Cloud-based MES | Plex | – Native cloud MES for manufacturing- Real-time production- Quality management | Cloud-first, multi-plant manufacturers |

| Oracle NetSuite | – Unified cloud platform for MES, ERP, and finance- Scalable operations | Small to mid-size manufacturers | |

| PINpoint MES | – The best MES software with no-code deployment- Error-proofing- Performance insights | Discrete manufacturers seeking fast adoption | |

| On-premises MES | DELMIAWorks | – ERP-centric MES with manufacturing intelligence- Traceability- Genealogy | Discrete and process manufacturing |

| SAP ME | – Centralized shop floor execution- Deep SAP ERP integration | Large-scale, complex operations | |

| Siemens Opcenter | – The best MES software with end-to-end execution and genealogy- Integrated quality control | High-compliance manufacturing environments | |

| Hybrid MES | Epicor Advanced MES | – Automated machine data collection- Real-time monitoring and alerts | Scalable manufacturing environments |

| Industry-specific MES | iBASEt | – Enterprise quality management- Compliance-driven production execution | Aerospace, defense, and complex manufacturing |

| AVEVA MES | – Real-time production visibility- Digital workflows and optimization | The best MES software for process-intensive manufacturing | |

| Critical Manufacturing | – Modular Industry 4.0 MES- Global production visibility | High-tech and global manufacturers | |

| Generic and Open-source MES | Infor MES | – Industry-specific execution- Advanced traceability and compliance | Regulated industries and large enterprises |

Quick comparison table of the 11 best MES software

Plex

Developed only for manufacturers, Plex is a manufacturing execution system presented as a natural cloud platform. Plex was created for the cloud from the beginning, therefore allowing quicker deployment and real-time visibility across production and quality activities rather than adjusting from an on-premises design. One place brings production management, plant floor control, quality, scheduling, and inventory together on the platform.

Among the best MES software choices now for companies stressing cloud adoption and operational openness, Plex is frequently considered.

Pros

– Native cloud MES built specifically for manufacturing

– Real-time production, quality, and inventory visibility

– Closed-loop quality management and plant floor control

– ERP integration for end-to-end operations

Cons

– Some workflows are not fully intuitive

– Smaller vendor size may limit development capacity

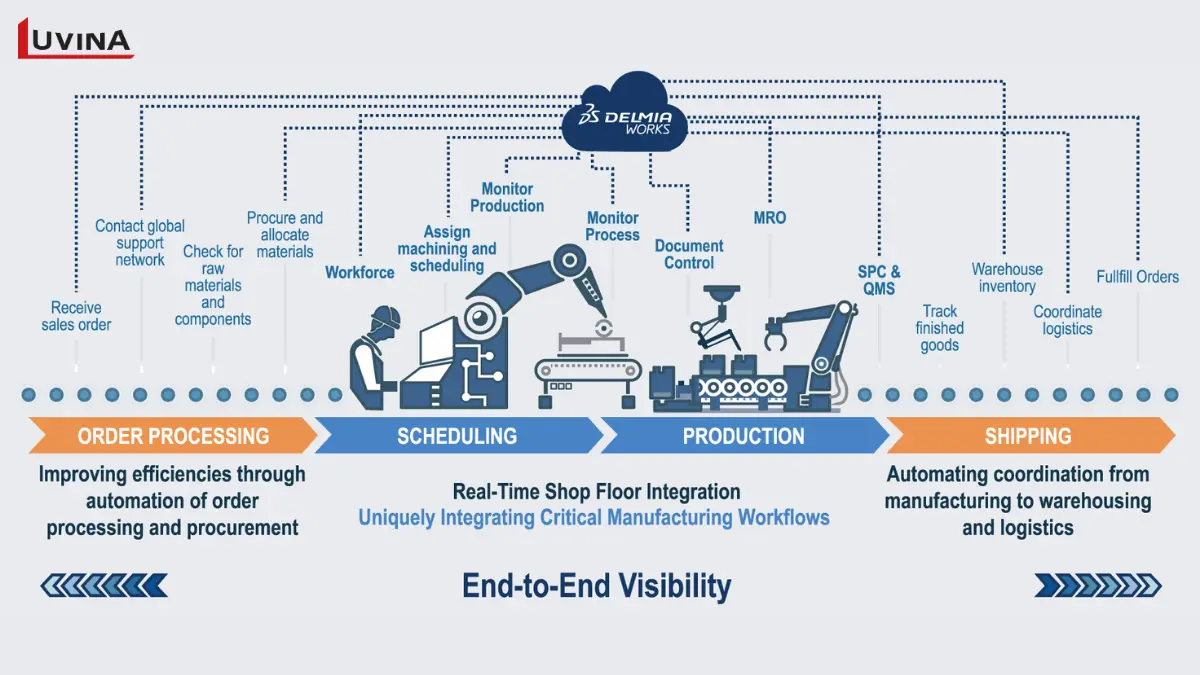

DELMIAWorks

Originally known as IQMS, DELMIAWorks is a top MES software and ERP platform created for discrete, repetitive, process, and manufacturing environments. Its MES offers producers flexible alternatives depending on their present IT environment, since it can be used as a separate system or closely integrated with an already operating ERP.

DELMIAWorks helps manufacturers manage production, inventory, and quality in a single system

While lean manufacturing tools improve consistency and efficiency, the best MES software enables real-time monitoring across traceability, inventory, and production.

Pros

– User-friendly interface with intuitive navigation

– Great integration between corporate and production activities

– Real-time production traceability and monitoring

– Encourages independent MES as well as ERP-integrated implementations

Cons

– Software upgrades may reset system settings

– Performance slowdowns and bugs reported during updates

Epicor Advanced MES

Built for producers who want great shop-floor visibility without being confined to a single deployment approach, Epicor Advanced MES is the best MES software. Support of cloud, on-premises, and hybrid systems makes it simpler to match with various IT approaches as companies expand.

Its interface is generally considered approachable compared to many enterprise systems, and the availability of add-on modules allows companies to extend functionality as needed. That said, the system’s more advanced capabilities take time to master.

Pros

– Easy-to-use interface as opposed to several business MES solutions

– Possibilities for flexible deployment: cloud, on-premises, or hybrid

– Real-time strong visibility into production and equipment performance

– Automation helps to make proactive decisions by cutting down on hand data gathering

Cons

– Advanced features and reporting have a steep learning curve

– System performance may lag with complex configurations

– Customization and integration can require dedicated IT resources

Infor

With the support of one of the world’s leading industrial software companies, Infor – one of the best MES software – is mostly concerned with manufacturing specific to the sector, providing solutions suitable for demanding operational and regulatory settings. Especially for businesses considering long-term scalability instead of rapid deployment, its rather intuitive interface and great configurability make it a frequently referenced point in any serious MES software comparison.

Infor is a top choice among the best MES systems for enterprise manufacturing

In-depth across production management, quality, and traceability sets Infor MES apart. Where compliance and serialization are essential, the platform is widely used in controlled industries including aerospace, food and beverage, and pharmaceuticals.

Pros

– Broad, enterprise-level functionality beyond core MES

– Industry-specific configurations that support compliance and traceability

– Scalable architecture suitable for multi-site and global operations

– Strong integration with ERP and other enterprise systems

Cons

– Higher licensing and long-term ownership costs

– Complex implementation and configuration for first-time users

– Reporting and analytics may require additional setup to unlock full value

iBase-t

As part of its broader Digital Operations Suite, iBase-t MES focuses on connecting production execution with quality, supplier management, and engineering systems. In many enterprise-level MES review discussions, iBase-t is often highlighted as the best MES software for its ability to handle strict compliance requirements and multi-layered manufacturing workflows rather than high-volume, fast-moving production lines.

Industries such as aerospace, defence, medical device manufacturers, and industrial equipment manufacturers benefit greatly from using iBase-t MES because these manufacturers require and demand a high degree of traceability, audit trails, and process control.

Pros

– Solid backing for sophisticated, controlled production surroundings

– Total quality, traceability, and compliance features

– Scalable, flexible architecture fit for big, multi-site companies

– Multiple integration possibilities with ERP, PLM, and engineering systems

Cons

– Steep learning curve due to system complexity

– The user interface can feel outdated and less intuitive

– Longer implementation and training timelines

– Integration and customization may require significant effort

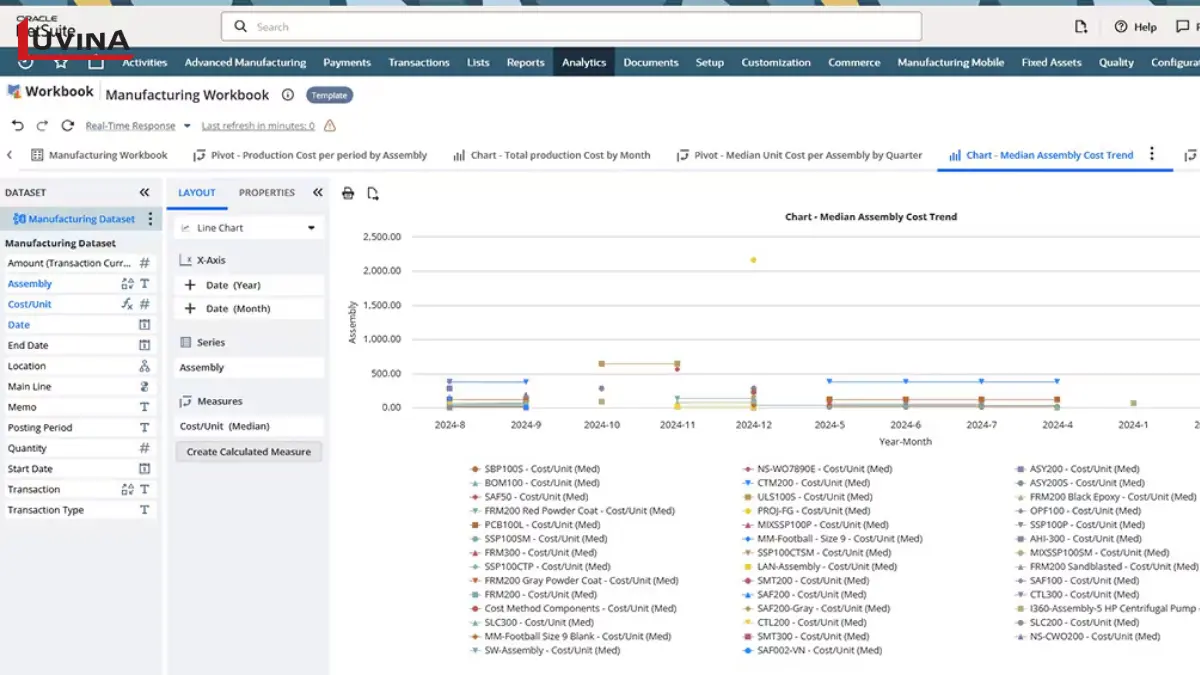

Oracle NetSuite

Though not a pure-play MES, Oracle NetSuite is still a realistic choice for smaller to medium-sized producers with less sophisticated surroundings. Being a cloud-native platform, NetSuite integrates in one system ERP, accounting, CRM, and supply chain management, together with limited manufacturing execution skills. This attracts companies that would rather use an all-in-one strategy than set up a discrete MES. NetSuite is occasionally regarded when operational simplicity and corporate-wide integration surpass deep production control in the choice of the best MES software.

Oracle NetSuite is the best fit for small to mid-size manufacturers

Pros

– A unified platform that includes CRM, finance, and manufacturing

– Deployment based on the cloud with little infrastructural requirements

– Robust financial and operational reporting

– Fits well for modest to medium-sized manufacturers.

Cons

– Limited depth in advanced shop floor control

– Costs increase as transaction volumes grow

– Not ideal for highly complex or regulated production environments

AVEVA

Known for enabling producers to link operations, information, and people across the value chain, AVEVA is one of the best MES software. Originally known as Wonderware MES, its MES offering is intended to enable challenging production systems needing great visibility, seamless integration, and scalable control. AVEVA MES aims to harmonize shop floor execution with corporate systems as part of more comprehensive manufacturing execution system solutions, therefore allowing manufacturers to minimize rework, raise quality, and react quickly to operational problems.

AVEVA MES grabs attention for its profundity and adaptability. Its capacity to change with various processes while keeping steady production monitoring and compliance is valued by producers in fields including food and beverage, pharmaceuticals, and automotive.

Pros

– Great real-time visibility into performance and manufacturing

– Adaptable to several manufacturing methods and scalable

– Strong quality control and traceability features

– Strong interaction with industrial automation systems and ERP

Cons

– Initial setup and configuration can be complex

– Steeper learning curve for new users

– Integration projects may require significant time and resources

– Higher infrastructure and implementation costs for advanced use cases

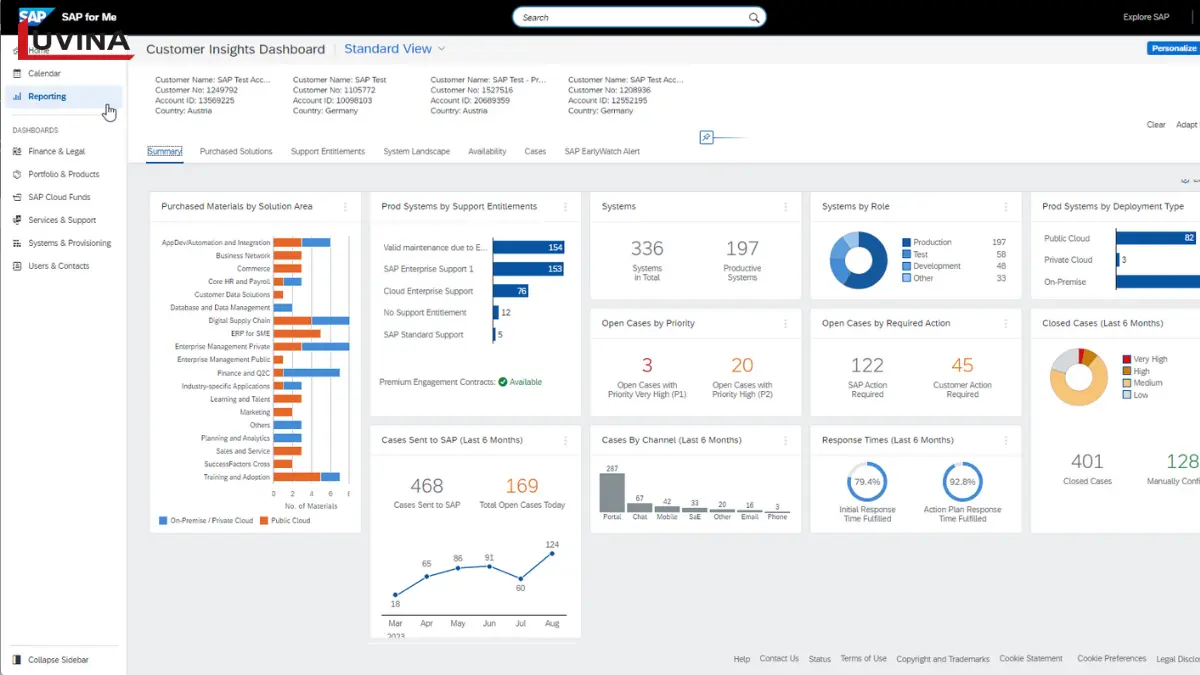

SAP ME

A fundamental building block inside the more general SAP production and ERP environment is SAP ME. Designed to cooperate closely with SAP S/4HANA and other SAP applications rather than as a separate tool, SAP ME offers companies end-to-end visibility from shop floor execution to commercial operations. Often taken for international manufacturers assessing the best MES software, SAP ME is especially useful when deep integration, sophisticated reporting, and corporate-wide standardization are most important.

SAP ME is the best manufacturing execution system for complex factories

SAP ME shines in handling high-volume, multi-site production with tight quality and traceability demands in actual applications. Its powerful data model allows for thorough monitoring of performance measures, inventory, and production.

Pros

– Deep integration with SAP ERP and supply chain systems

– Strong real-time production visibility and reporting

– Robust quality control, traceability, and defect tracking

– Designed for complex, large-scale manufacturing operations

Cons

– Complex user interface with a steep learning curve

– High implementation and total cost of ownership

– Customization and integration can be time-consuming

– Not well-suited for smaller manufacturing organizations

Siemens

Built on Siemens’s extensive experience in industrial automation and digital twins, Siemens MES is distributed via the Opcenter Execution portfolio. To enhance quality, traceability, and operating control, this approach links shop floor execution to corporate systems. Organizations looking for complex process orchestration, robust compliance support, and perfect ERP and PLM system integration frequently choose Siemens as the best MES software.

Across several sites, Siemens MES offers a single view of quality, materials, and production data. Its scalability and capacity to underpin consumer products, pharmaceuticals, chemicals, and food and beverage, as well as other sectors, appeal to manufacturers.

Pros

– Great integration with ERP, PLM, and industrial automation

– Advanced quality management, genealogy, and compliance assistance

– Scalable for high-complexity production and multiple locations

– In-depth industry knowledge and digital twin abilities

Cons

– Expensive licensing and implementation costs

– Steep learning curve as a result of system intricacy

– Special skills are needed for customizing and deployment

– May be overpowered for smaller or less complex operations

Critical Manufacturing MES

A contemporary and very customizable platform called Critical Manufacturing MES is meant. It keeps strict control over compliance and quality procedures while facilitating end-to-end manufacturing activities. For organizations needing great visibility across worldwide production and the flexibility to rapidly adjust to shifting demand or regulatory demands, Critical Manufacturing typically jumps out when considering the best MES software.

Critical Manufacturing MES provides flexible solutions for compliance and production visibility

By linking corporate systems with manufacturing automation, the platform is excellent at enabling closed-loop quality and real-time intelligence across many sites. Because its design fits nicely with Industry 4.0 projects, it’s a perfect match for businesses including medical devices, semiconductors, electronics, and other high-tech sectors.

Pros

– Powerful backing for closed-loop quality, compliance, and traceability

– Exceptionally customizable for complicated, high-tech production

– Perfect visibility over worldwide and multi-site operations

– Built with Industry 4.0 readiness in mind

Cons

– Implementation can be complex and resource-intensive

– Steeper learning curve for teams new to advanced best MES software

– Best suited for mature manufacturing environments rather than simple use cases

PINpoint

Built as a no-code platform, PINpoint – one of the best manufacturing execution systems – focuses on enforcing standardized processes, eliminating manual errors, and turning production data into actionable insights. It is often attractive due to its out-of-the-box functionality and shorter time to value compared to more complex enterprise MES platforms.

Usability and practicality on the shop floor make PINpoint unique. The system allows electronic work orders, error-proofing, and performance heatmaps to help teams rapidly spot bottlenecks and quality problems. Although it might not provide the same depth as very flexible corporate MES solutions, PINpoint is appropriate for businesses that give operational discipline, ongoing improvement, and simplicity of adoption top priority.

Pros

– No-code platform with fast deployment and high usability

– Strong focus on error-proofing and standardized processes

– Clear production visibility through performance heatmaps

– Designed specifically for discrete manufacturing environments

Cons

– Less suitable for highly complex or heavily regulated industries

– Limited depth compared to large enterprise MES platforms

– Advanced customization options are more constrained

Best Open-source MES Software Options

Open-source MES is not a shortcut to enterprise MES. It is a trade-off between flexibility and responsibility. It is best suited for manufacturers with strong in-house technical teams who value flexibility over turnkey solutions. It works particularly well for job shops, SMEs, or organizations building a modular MES stack instead of relying on a single all-in-one platform.

When evaluating the best MES software in the open-source landscape, it’s important to understand each tool’s scope, strengths, and limitations before aligning it with your operational goals.

Below is a concise comparison of notable open-source and community-driven MES-related solutions, highlighting their focus areas and ideal use cases.

| Software | Type of MES software | MES scope | Target use case |

| IMES | Lightweight job-shop MES | Basic job routing and order tracking | Small job shops needing core MES functions |

| qcadoo MES | Web-based open-source MES | Production tracking and scheduling | SMEs transitioning to digital manufacturing |

| Libre – by Spruik | IIoT-focused MES | Monitoring and performance analysis | IIoT-driven shop-floor visibility & analytics |

| frePPLe | Planning-oriented MES component | Demand planning and scheduling | Complex production planning (not execution) |

IMES

IMES is a community-driven, open-source MES designed as a lightweight foundation for job-shop manufacturing environments. Instead of trying to cover every layer of enterprise operations, IMES focuses on essential shop-floor execution tasks such as work-order tracking and basic production data capture. This makes it a practical option among the best MES systems for small to mid-size job shops that want MES functionality without the complexity or overhead of a full ERP-centric system.

Pros

– Built specifically for small and mid-size job shops with straightforward workflows

– Covers core MES functions

– Lightweight architecture

Cons

– Limited feature set

– Minimal industrial integrations and documentation

– A smaller open-source community may limit long-term support and updates

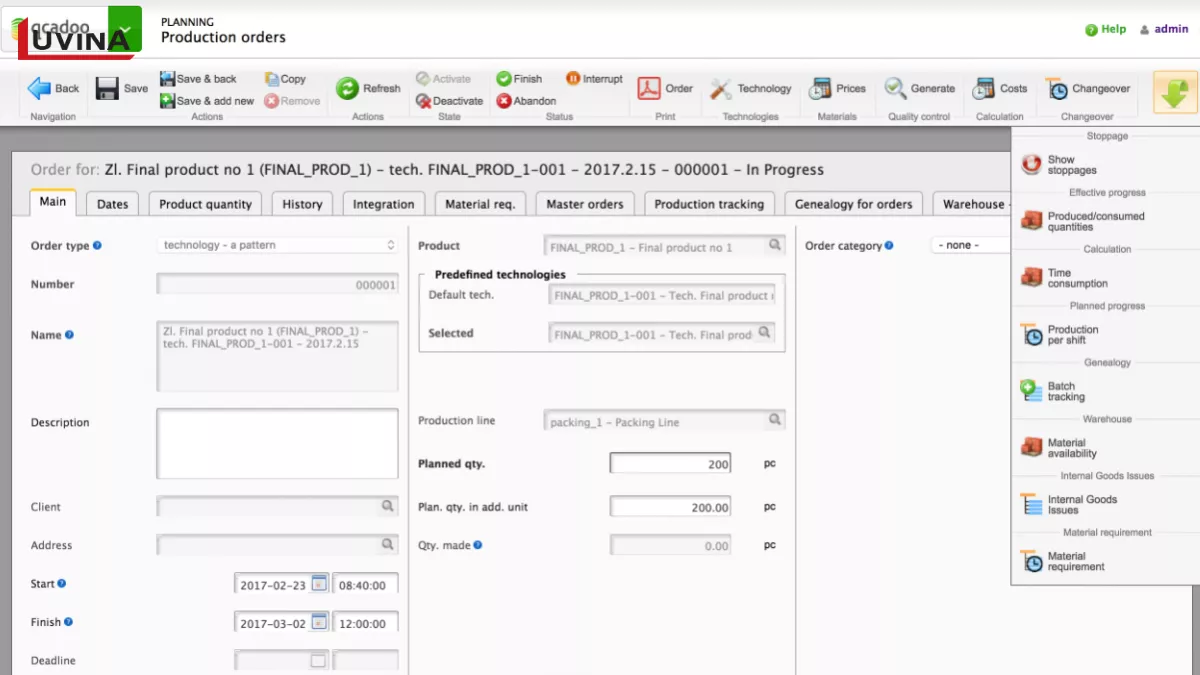

qcadoo MES

Built for small and medium-sized producers starting their digital transformation path, qcadoo MES is a browser-based, open-source manufacturing execution system. Through a clear web interface, the platform aims to make production data available so that teams may handle job orders, keep tabs on production development, and track inventory conditions without installing costly on-premises infrastructure. qcadoo MES presents a workable starting point for businesses considering the best MES software choices before investing in more extensive commercial systems, with its Community Edition issued under an open-source license and available via GitHub.

qcadoo MES is an open-source MES manufacturing execution system for SMEs

Pros

– Web-based interface

– Supports core MES functions

– Open-source Community Edition suitable for SMEs with limited budgets

Cons

– Limited public information on industrial protocol support and deep system integrations

– Community Edition may receive slower updates compared to the commercial SaaS version

– Advanced scalability and enterprise features are more restricted than in full-scale MES platforms

Libre – by Spruik

Developed with a major emphasis on shop-floor performance monitoring and data visualisation, Libre is an open-source MES project. Designed to integrate with IIoT stacks, Libre enables producers to nearly instantaneously gather, arrange, and analyse production data. The platform lets teams clearly see their downtime, process steps, and operational performance using widely used technologies like Grafana, InfluxDB, and PostgreSQL, therefore making it a viable choice for companies assessing best MES software solutions based on data-driven manufacturing.

Pros

– Strong support for shop-floor data capture and performance analytics

– Integrates well with popular IIoT and visualization tools like Grafana and InfluxDB

– Open-source and flexible, suitable for customized monitoring-focused MES setups

Cons

– Primarily focused on monitoring and performance, not a full-featured MES

– Lacks native scheduling and quality management capabilities

– Requires additional integration effort with the data infrastructure to deliver full value

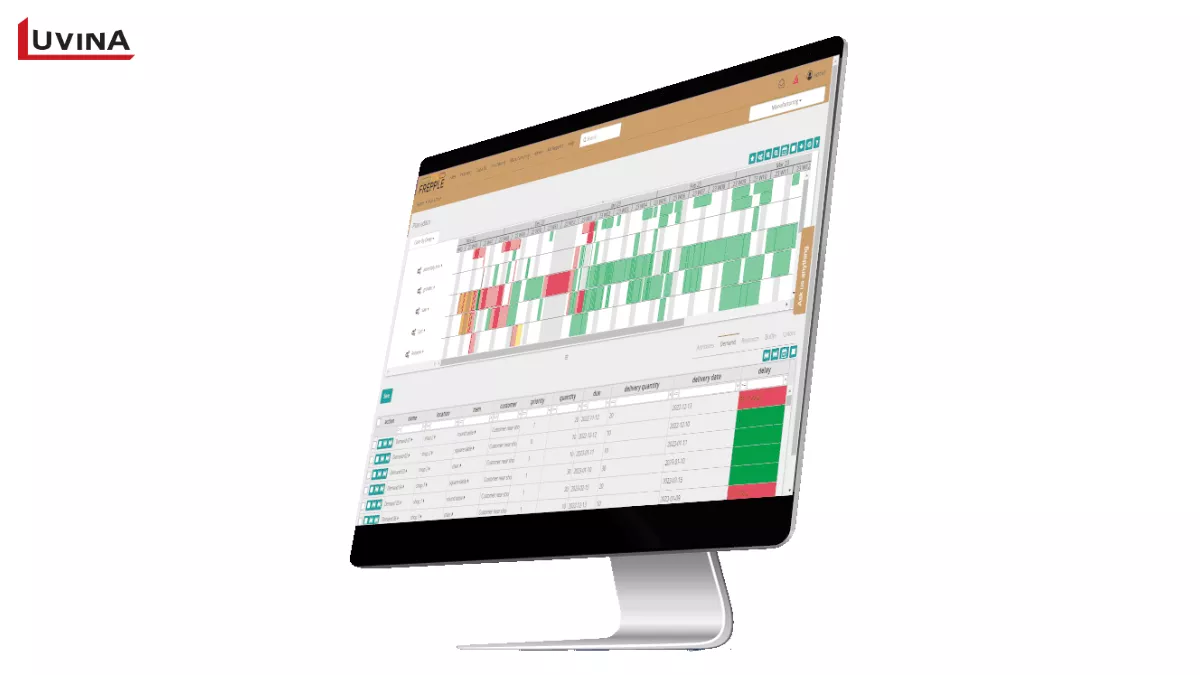

frePPLe

frePPLe is an open-source tool focused on demand planning and production scheduling rather than shop-floor execution. Instead of replacing the best MES software, it is often used alongside execution platforms to strengthen planning accuracy and capacity optimization. In open-source manufacturing stacks, frePPLe is commonly paired with execution-focused tools to form a more complete alternative to best-of-breed software used in complex production environments.

frePPLe focuses on optimizing production scheduling and demand planning

Pros

– Strong capabilities for demand forecasting and production scheduling

– Algorithm-driven planning supports complex constraints and scenarios

– Scales effectively as production volume and planning complexity increase

Cons

– Not a full manufacturing execution system

– Does not support real-time shop-floor execution or quality control

– Requires integration with other tools to cover end-to-end MES needs

Pro tips:

– Use IMES as a lightweight execution layer for job-shop environments where basic work-order tracking is enough.

– Position qcadoo MES as the core execution system for SMEs, especially when you need a browser-based MES with minimal setup.

– Deploy Libre strictly for performance monitoring and shop-floor visibility, not as a full execution system.

– Combine frePPLe for planning and scheduling with IMES or qcadoo MES to build a modular stack that approaches best MES software flexibility without enterprise-level complexity.

Future Trends in MES Software

Along with Industry 4.0, IoT, and AI, MES software is quickly changing. Defining expectations for the best MES software in terms of speed, accuracy, and operational visibility, modern platforms are turning toward real-time data gathering, predictive analytics, and more informed decision-making on the shop floor.

Another major trend is deeper integration with ERP, PLM, and supply chain systems to give manufacturing activities an end-to-end perspective. Simultaneously, rising demand for customisation implies that MES software solutions progressively need custom development and customised implementation to suit particular processes, industries, and scaling requirements – hence, flexibility becomes a key consideration in assessing the best MES software.

As MES becomes more modular and integration-driven, off-the-shelf systems alone are often not enough. In this situation, collaborating with seasoned custom development and specialized MES deployment teams is needed. The appropriate partner helps manufacturers cut implementation time, manage expenses, and meet operational objectives more quickly. Businesses like Luvina provide established knowledge in creating adaptable MES systems suited to actual manufacturing demands; therefore, we are a great pick for organizations wanting to quickly transition from plan to implementation.

Looking for a tailored MES?

Contact Luvina for custom development and implementation support.

Conclusion

Choosing the best MES software for your company entails aligning technology with your manufacturing scale, process complexity, and long-term goals – not about finding a single “ideal” solution.

We hope this resource has cleared the MES terrain, offered real comparison benchmarks, and given you a more defined direction in choosing MES solutions for your manufacturing setting. MES can be a solid basis for operational excellence, ongoing development, and future-ready manufacturing if you use the right approach.

Resources

- https://foodready.ai/blog/best-mes-software/

- https://mdcplus.fi/blog/top-free-mes-systems-manufacturing-execution/

- https://www.flexwareinnovation.com/11-criteria-and-questions-to-consider-when-selecting-a-manufacturing-execution-system-mes/

- https://www.42-q.com/blog/news/5-types-of-mes-systems/

- https://www.thirdstage-consulting.com/top-10-manufacturing-systems/

- https://www.gartner.com/reviews/market/manufacturing-execution-systems

- https://www.selecthub.com/c/mes-software/

- https://solutionsreview.com/enterprise-resource-planning/the-best-manufacturing-execution-systems-mes-to-consider/

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter