PLM software for manufacturing helps manufacturers transform under mounting pressure to swiftly innovate, lower costs, and uphold quality while handling difficult product data and development cycles. PLM software helps makers to simplify each stage of a product’s life, therefore improving collaboration, visibility, and time to market.

We will look in this comprehensive guide at how PLM software helps manufacturing processes, some of the top PLM software available on the market, difficulties, and best practices during deployment.

Why PLM Software Is Critical in Modern Manufacturing

Product Lifecycle Management (PLM) software is a system that enables producers to oversee all aspects of a product, from initial concept to design, manufacturing, maintenance, and even disposal. Consider PLM software for manufacturing a digital spine that links every item’s facts, procedures, and teams in the course of the product’s life.

PLM is essential for allowing manufacturers to create a “digital thread,” a continuous flow of data linking design, engineering, manufacturing, and service in real time, supporting digital transformation and Industry 4.0. All while preserving product quality and legal compliance, this integration fosters agility, creativity, and quick response to changing market needs.

Without PLM, producers run across isolated information, fractured systems, manual mistakes, and inadequate version control. These difficulties obstruct cooperation, delay time-to-market, and raise operational dangers. In contrast, contemporary PLM solutions bring together the whole product value chain on a single digital platform, enabling teams to innovate quickly, make better judgments, and drive constant improvement.

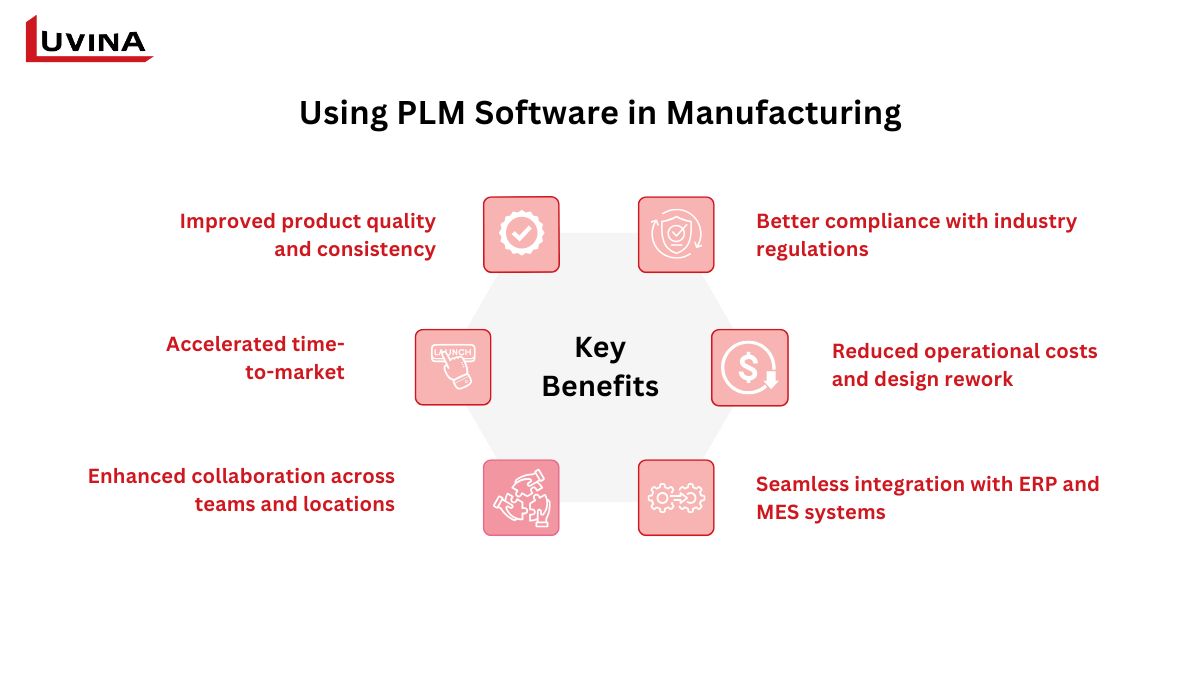

Key Benefits of Using PLM Software in Manufacturing

Using PLM software for manufacturing gives one more than only digital organization. It forms an intelligent network that helps every stage of the product lifecycle. Manufacturers can anticipate the following main advantages:

- Improved product quality and consistency

PLM reduces mistakes and misunderstandings by allowing clear processes and constant design practices. Its traceability capabilities guarantee every part and function is recorded, therefore promoting dependable engineering all over product lines and quality assurance.

- Accelerated time-to-market

PLM accelerates the trip from idea to production by simplifying product development and robotizing change management. With coordinated plans and directions, teams can swiftly react to comments and release fresh goods more quickly.

- Enhanced collaboration across teams and locations

With a single source of truth, PLM helps to remove silos among divisions and locations. Real-time data and smooth cooperation across cross-functional teams (whether in engineering, compliance, or manufacturing) are available.

- Better compliance with industry regulations

PLM streamlines compliance management using internal support for ISO, FDA, and other worldwide standards. It lets manufacturers across suppliers and sites track variations, uniform documentation, and provide product records ready for audits.

- Reduced operational costs and design rework

Early PLM helps find inefficiencies, so optimizing design and production processes to reduce costs. Clear product requirements, precise models, and proper validation of changes before release help to reduce rework and recalls.

- Seamless integration with ERP and MES systems

Combined with ERP and manufacturing execution systems (MES), PLM offers complete visibility. Design and production are linked on this integrated platform, which also facilitates better execution, more agile decision-making, and smarter planning.

Best PLM Software for Manufacturing [latest updated]

The right PLM choice you make could greatly affect your level of innovation, growth potential, and competitiveness retention. The best PLM software for manufacturing this year is represented by the following platforms with strong features, scalability, and support for next-generation technologies. Let’s investigate the leading candidates.

| PLM software | Best for | Key features | Best-suited industries | Integrations |

| Aras Innovator | Mid-size to large enterprise with complex product lifecycle | BOM, CAD, Digital Twin, Open APIs, Low-code | Industrial, Automotive, Engineering | MCAD/ECAD, MS Office. |

| Siemens Teamcenter | Large enterprises | BOM, CAD, Digital Twin, Enterprise Scalability | Automotive, Aerospace | NX, Solid Edge, SAP, Oracle |

| PTC Windchill | Complex products | Configuration mgmt, Change control, IoT-ready | Industrial, MedTech | Creo, ThingWorx, SAP |

| Autodesk Fusion 360 Manage | SMEs to mid-size teams | Cloud-native PLM, Custom workflows | Consumer goods, Design firms | Autodesk, Salesforce, Slack |

| Dassault Systèmes ENOVIA | Global collaboration | Compliance, Lifecycle mgmt, 3DEXPERIENCE cloud | Aerospace, High-tech | CATIA, DELMIA, SAP |

| Arena PLM | Cloud-first product teams | BOM, quality management, and Regulatory compliance | Electronics, MedTech, IoT | NetSuite, Jira, Salesforce |

| Oracle Agile PLM | Oracle ERP ecosystems | Product data, Costing, Component tracking | Pharma, High-tech | Oracle Cloud, SAP, Agile ERP |

| Upchain (PTC) | Mid-market manufacturers | User-friendly, CAD-neutral, Fast deployment | SMEs, OEM suppliers | SolidWorks, AutoCAD, Jira |

1. Aras Innovator

Aras PLM is the product lifecycle mangement platform, meant to control all product lifecycle stages, from the beginning idea to the conclusion of life, built by Aras Corporation. The Aras PLM system offers businesses a single platform to arrange design, development, and production activities effectively.

Fundamentally, the Aras PLM platform is a real-time collaborative environment where cross-functional teams may work together, rather than only software. It guarantees accuracy, openness, and simplified cross-department communication by offering one source of truth for product information.

You can learn more about the platform in our in-depth article analyzing the Aras Innovator’s features and architecture.

2. Siemens Teamcenter

Siemens Teamcenter is a leading PLM software for manufacturing, trusted by global enterprises to streamline product development and digital collaboration. Designed as part of Siemens’ broader Digital Innovation Platform, Teamcenter offers deep integration across business domains, connecting engineering, manufacturing, service, and supply chain on a single, secure framework.

Teamcenter helps producers to innovate faster, increase productivity, and guard product data across the lifetime by combining specific domain applications with common digital services. Its performance-improving qualities foster efficient processes, lower development costs, and guarantee teams can produce high-quality products with more speed and accuracy.

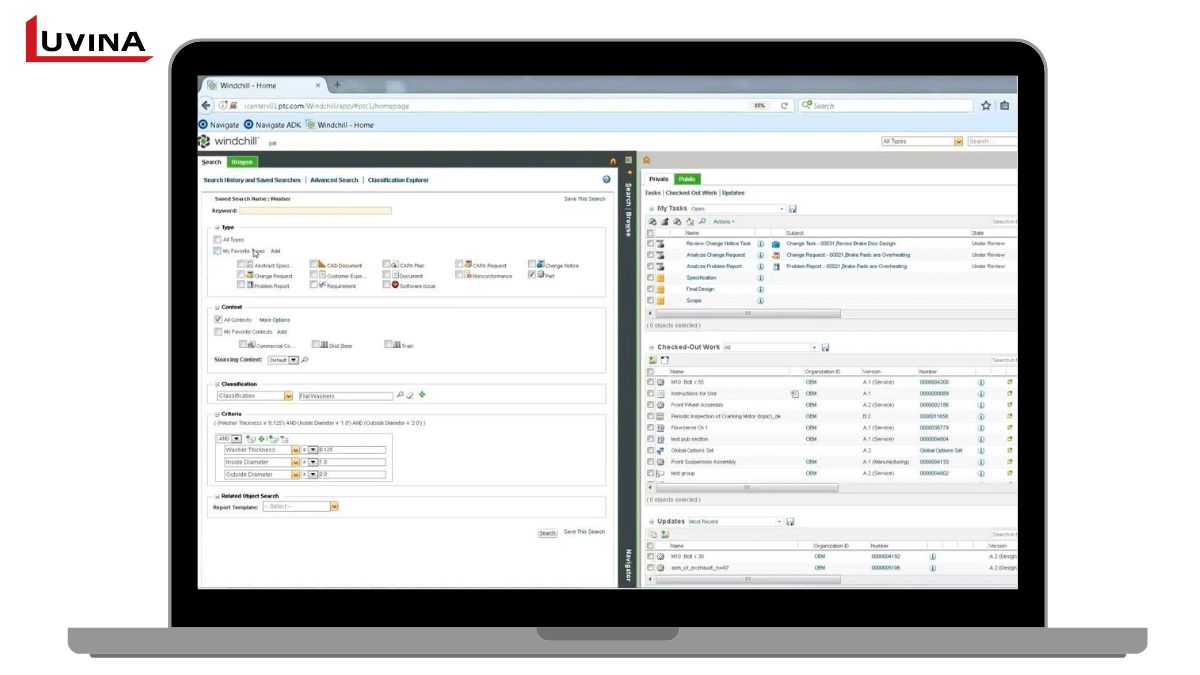

3. PTC Windchill

PTC Windchill, a strong product lifecycle management tool, offers an organizationally consistent, real-time perspective of product data. It gives all teams access to a single source of truth, enabling faster cross-functional collaboration.

Windchill’s two deployment choices (cloud or on-premise) provide secure access to current operational data, therefore lowering IT overhead and boosting productivity. Its combination with IoT technologies lets producers innovate faster, raise product quality, and bring goods to market with more accuracy and speed.

4. Autodesk Fusion 360 Manage

Manufacturing Autodesk Fusion 360 Manage is cloud-based PLM software for manufacturing by links teams, processes, and data on one organized platform, thereby simplifying product development. End-to-end lifecycle management helps companies automate processes, lower delays, and keep a steady flow of information across divisions and worldwide sites.

Fusion 360 Manage enables teams to make quicker decisions, enhance cooperation, and stay aligned throughout the whole product path with real-time access to product data from anywhere.

5. Dassault Systèmes ENOVIA

Among the best PLM software for manufacturing, Dassault Systèmes ENOVIA, part of the 3DEXPERIENCE platform, gives product data management a consolidated and safe environment. By centralizing data and enabling access anytime, anywhere, ENOVIA promotes effortless cooperation across teams, divisions, and even international sites.

While this robust tool guarantees data security and dependability across the whole product lifecycle, it enables companies to drive innovation, keep regular product development processes, and constantly enhance performance.

6. Arena PLM

Modern manufacturing settings are where Arena PLM – a cloud-native solution – aims to simplify product development, quality control, and regulatory compliance. Arena enables businesses to speed innovation while preserving control and visibility throughout the product lifecycle by consolidating product data, teams, and workflows onto a single, secure platform.

Arena simplifies team collaboration and scaling with role-based access, internal compliance tools, and a low total cost of ownership. Some users have noted restrictions in customer service responsiveness and project navigation.

7. Oracle Agile PLM

From idea to end-of-life, Oracle Agile was designed to maximize every stage of the product lifecycle. Using Oracle’s vast experience and established best practices, this platform enables companies to simplify product development, boost collaboration, and drive innovation across divisions.

Oracle Agile PLM enables businesses to accelerate innovation and maintain high product quality

Oracle Agile PLM is built for performance and scalability, enabling manufacturers to maintain security, increase operational efficiency, and react quickly to market demands. It is especially appropriate for companies looking to speed product innovation while maintaining data integrity and long-term profitability.

8. Upchain (PTC)

Manufacturing firms, particularly small and medium-sized enterprises seeking to simplify collaboration and product data management, will find Upchain, cloud-based PLM software for manufacturing, especially suitable. Upchain eases difficult processes without compromising data security or control using real-time collaboration tools, CAD and Microsoft Office integrations, and complete BOM tracking.

By acting as a single source of truth, the platform guarantees that teams, anywhere, have constant access to important papers and live project updates. For expanding manufacturers requiring agility and openness, its flexible API connections and ECR (Engineering Change Request) features make it a strong candidate.

Though Upchain’s pricing structure is open and affordable, its instructional material is a bit dated, which could pose a learning curve for fresh users.

PLM Implementation Challenges and Best Practices

Using PLM software for manufacturing can significantly improve product development, but it also raises several technical and organizational difficulties.

Data moving is among the most common challenges. Moving large volumes of historical product data into a new system calls for meticulous preparation to ensure accuracy, consistency, and compliance. Simultaneously, combining PLM with current business systems usually raises issues with interoperability, including data integration challenges and API restrictions. Another major obstacle is user adoption; employees may oppose change out of either unwarranted fear of disturbance to their procedures or lack of knowledge of new tools.

Following a set of recommended standards will help to lower these dangers:

- Executive buy-in: Early leadership backing will help to drive resource allocation and create a culture receptive to change, using continuous communication on the advantages.

- Phased rollout: Evaluate present processes, find gaps, and progressively refine workflows to reduce disturbance by gradually implementing the PLM system.

- Cross-functional team involvement: Involve champions across several divisions to own, offer direction, and guarantee defined role responsibilities during the implementation.

- Vendor training & ongoing support: Offer individualized, role-specific instruction and constant support to aid consumers in fitfully adapting and maximizing their use of the program.

Need a Scalable PLM Solution? See How Luvina Can Help

Luvina provides customized product lifecycle management solutions meant to help companies of all sizes, from tiny businesses to major corporations, for producers looking for dependable and expandable PLM software for manufacturing.

Luvina’s tailored PLM systems improve supply chain agility, uphold business continuity, and offer strong data governance and traceability – all while easily connecting with your current ERP networks. With years of experience on top platforms like Aras Innovator, internationally respected by industry leaders like GE, Honda, and Motorola, we can provide strong features, including multi-CAD data management, project oversight, and change control.

Learn more about what Aras can do in action:

Dedicated to the best standards, Luvina offers seamless communication skills in English and Japanese as well as thorough IP protection grounded on worldwide norms. Always accessible across time zones, our staff guarantees continuous support and training to help you get the most out of your PLM investment. ISO 9001 and CMMI Level 3 credentials attest to our commitment to excellence.

Prepared to change your product lifecycle with a scalable, secure, and effective PLM solution? Get in touch with Luvina right away to find out how we may help you customize the ideal system to match your manufacturing needs.

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter