Studies reveal that inadequate inventory monitoring and unconnected data sources cause financial losses for more than 60% of logistics businesses annually. Many are hence looking to the ERP system for logistics, a single platform that consolidates order processing to supply chain and inventory control.

We will reveal in this article how ERP solutions are revolutionizing the logistics sector, the typical difficulties companies run into during execution, and the most current solutions on hand.

Check our full guide on ERP software development if you are unfamiliar with ERP or are thinking of creating one for your organization.

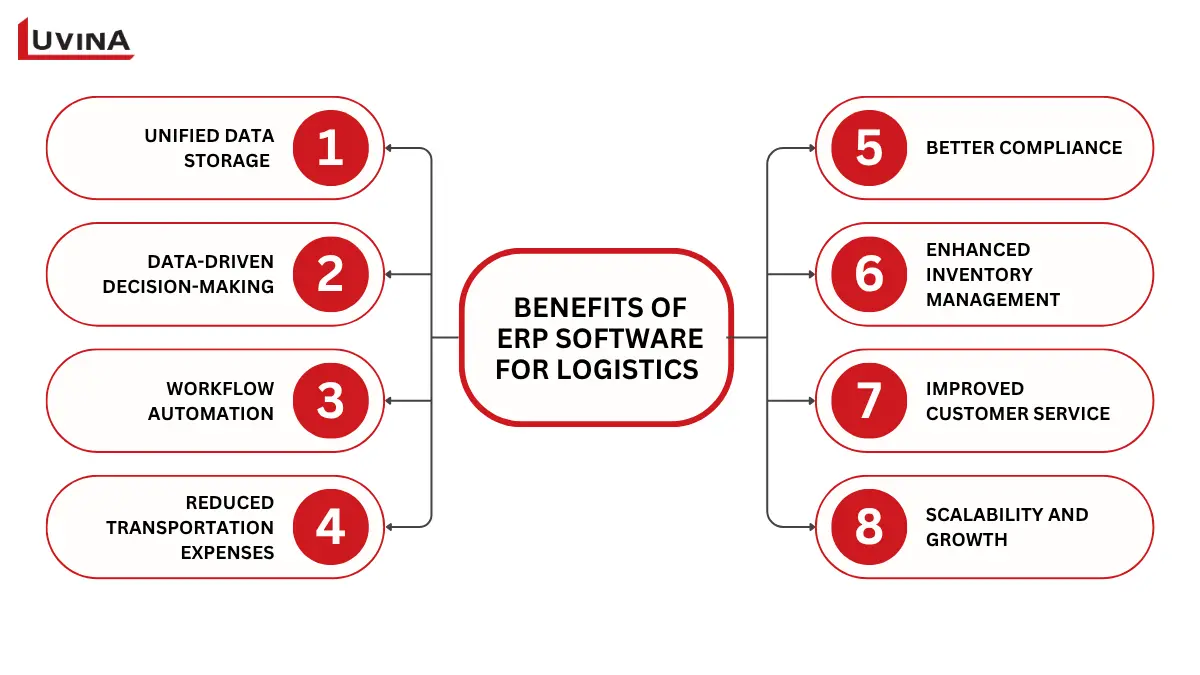

Benefits of ERP Software in the logistics industry

Helping companies reduce expenses, increase visibility, and raise accuracy, the ERP system for logistics companies serves as a central hub connecting finance, inventory, and operations data. Companies may remove delays, improve communication, and make decisions based on real-time insights rather than speculation by integrating all procedures via the ERP system for logistics.

Implementing an ERP system in logistics offers several major advantages:

Unified data storage

With the use of ERP software for logistics, all data will be maintained in a single hub, eliminating data silos, ensuring accuracy, and allowing all departments to access the same trusted source of truth.

Data-driven decision-making

Thanks to the ERP system for logistics, managers can review personalized reports and performance dashboards. Each decision is voted on based on data that is current and accurate.

Workflow automation

ERP systems save time and reduce error costs by automating repetitive tasks such as invoices, order processing, maintenance scheduling, and others. Teams could focus on strategic tasks instead of tedious processes.

Reduced transportation expenses

Logistics firms can reduce transportation costs by evaluating fleet performance, fuel consumption, and load optimization as it relates to the time of trips. They will be able to evaluate and track all aspects of prediction maintenance, and based on the analytics, will be able to plan schedules relating to routing and distributing resources.

Better compliance

The ERP system for logistics firm makes it easy to adhere to safety, customs, and transportation rules. It guarantees businesses stay in line with worldwide and local standards by keeping thorough audit trails and paperwork orderly.

Enhanced inventory management

One of the most important applications of IoT in logistics, ERP offers real-time stock tracking and intelligent replenishment warnings. Companies can maintain appropriate inventory levels, prevent overbuying, and avoid stockouts, hence creating a more effective supply chain.

Improved customer service

As workflows are processed faster between orders and the addition of real-time tracking and updates, customer satisfaction can improve. Your firm will have the opportunity to build trust and improve its repeat business by resolving issues quickly.

Scalability and growth

ERP often has a modular structure that allows for features to be added and new warehouse or service locations to be added when the company expands. Deployment can be on-premise, hardware, or cloud-based!

Challenges in implementing ERP in logistics

ERP can simplify logistics, but its implementation brings new challenges that require careful navigation. Common challenges encountered by organizations implementing ERP in logistics and supply chain management include:

– Upfront costs: Utilizing an ERP for logistics requires a considerable upfront investment in the IT backend, software licensing fees, and training for employees using the system. While all of these costs are quite considerable, most are ultimately mitigated over time with process efficiencies and decreased operational waste.

– Change management/user acceptance: When adopting a trimmed process, the existing process requires adjusting to new technology; hence, there are always cultural considerations. For your workforce to experience full utilization of ERP processes for logistics, they must navigate the cultural change of an adjustment in their duties. By remaining communicative, with constant reminders and training, you prepare them to have full acquiescence to the modified ERP-driven process.

– Integration with legacy systems: Many logistics firms still use legacy tools, so the new ERP must integrate smoothly with them. Each tech is now a user of some capacity in the latest ERP, ensuring external compatibility is as cumbersome and frustratingly drawn-out as ensuring users’ compatibility with the changes. Preparing well in advance can play a significant role in diminishing the potential for data conflicts or process outages.

– Customization and data migration: Each ERP for logistics company has particular procedures, hence system modifications are needed to meet its needs. Too much tailoring, though, can lengthen project timelines and raise risks. Similarly, moving great amounts of historical data calls for thorough verification to avoid data loss or inconsistencies.

Top ERP solutions for logistics

Choosing a good ERP system for logistics will determine how well a business manages its supply chain, inventory, and delivery. The following systems are the top ERPs for supply chain management and logistics performance enhancement, whether a business needs automation, scalability, or real-time visibility into processes.

1. SAP S/4HANA for Logistics

SAP S/4HANA is an advanced and powerful ERP system for logistics, particularly well-suited for organizations with complex global logistics. It includes real-time data processing and the capability for AI-enabled analytics to enhance demand forecasting, warehouse coordination, and transportation management. There are a number of advantages for companies, including greater shipment transparency, accuracy in order fulfillment, and accelerated decision-making.

Best for: Large companies and multinationals needing complete visibility and control over their supply chain and logistics processes from end-to-end.

2. Oracle NetSuite ERP

Oracle NetSuite ERP is another robust cloud-based ERP system for logistics that improves finance, inventory, and order management. NetSuite helps logistics businesses bring their functions together on one platform to reduce delays and waste. A good option for large logistics companies that are looking for a centralised view while offering flexibility, NetSuite will help improve allocation and forecasting, utilizing predictive analytics and reporting automatically.

Best for: Mid-size to large logistics companies looking for a scalable ERP that is cloud-first.

3. Microsoft dynamics 365 supply chain management

Microsoft Dynamics 365 Supply Chain Management offers one of the best ERP systems for supply chain management solutions that also offer a functional ERP and CRM. It provides organizations with end-to-end visibility into operations, as well as utilizes AI capabilities to improve demand planning and customer service. Organizations using Microsoft Dynamics can benefit from using Power BI and Azure compatibility to get insights from their organizations and act utilizing data for real-time logistics.

Best for: Large organizations and 3PL providers who want flexibility in a cloud ERP, along with deep integration capabilities with Microsoft products.

4. Infor cloudSuite supply chain

For businesses that desire a cloud-based ERP software for logistics to provide industry-specific capabilities, Infor CloudSuite Supply Chain provides a cloud solution tailored for the logistics industry. It is especially good in supplier coordination, transport planning, and warehouse automation. Infor’s incorporated machine learning and analytics solutions enable companies to forecast inventory needs and reduce stockouts, hence guaranteeing seamless logistics performance.

Best for: Logistics companies requiring cloud scalability and vertically oriented features.

5. Epicor ERP

Epicor ERP delivers a dynamic ERP system for logistics that reduces order tracking, distribution, and demand forecasting. Logistics companies are able to enhance data accuracy and reduce manual activities by emphasizing operational efficiency and leveraging automated and tracked reporting. Epicor is optimal for mid-sized organizations seeking a more transparent view of supply chain operations with the flexibility to adjust and change without being locked into rigid systems.

Best for: Mid-sized logistics and distribution organizations needing a blended mode of deployment and an efficient plan.

6. Acumatica cloud ERP

Perfect for expanding businesses, Acumatica cloud ERP offers a cheap and adaptable ERP system for logistics. Its integrated modules for inventory, delivery, and accounting, as well as its ease of use, will also keep departments aligned. Acumatica’s cloud technology can also provide remote access and scalability.

Best for: Companies looking for a scalable, cloud-based ERP software that has a low up-front licensing professionally.

7. Odoo ERP (Logistics Module)

Offering modular instruments for logistics management, Odoo is an open-source ERP system. Users can customize and combine inventory, fleet, and procurement modules to meet corporate demands. Odoo gives companies the ability to automate chores, enhance tracking, and simplify processes without too much expense as a flexible ERP for logistics company. For small logistics companies looking for flexibility, it is an affordable solution to their open-source functionality.

Best for: Small-to-midsized logistics companies looking for open-source affordability and flexibility.

8. Sage X3

Among the top ERP systems for supply chain management solutions for mid-sized logistics organizations on a global expansion plan, Sage X3 supports multiple currencies and languages. Capable of enhancing warehouse, distribution, and financial management, it provides advanced tools to track inventories and maintain regulations while delivering comprehensive logistics activities visibility and delivery assurance in all international locations.

Best for: Mid-sized logistics organizations with growth opportunities and multi-entity operations.

9. Syspro ERP

The Syspro ERP features strong inventory, warehouse, and order management features that actually help logistics and distribution companies. The system’s combined architecture allows full supply chain visibility and connects logistics and manufacturing activities. Flexible and designed for all different-sized organizations, Syspro can be deployed on-premise or in the cloud. This logistics ERP has significant flexibility and reporting beneficial for managing multi-warehouse operations efficiently and effectively.

Best for: Logistics and distribution companies needing great flexibility and integration capacity.

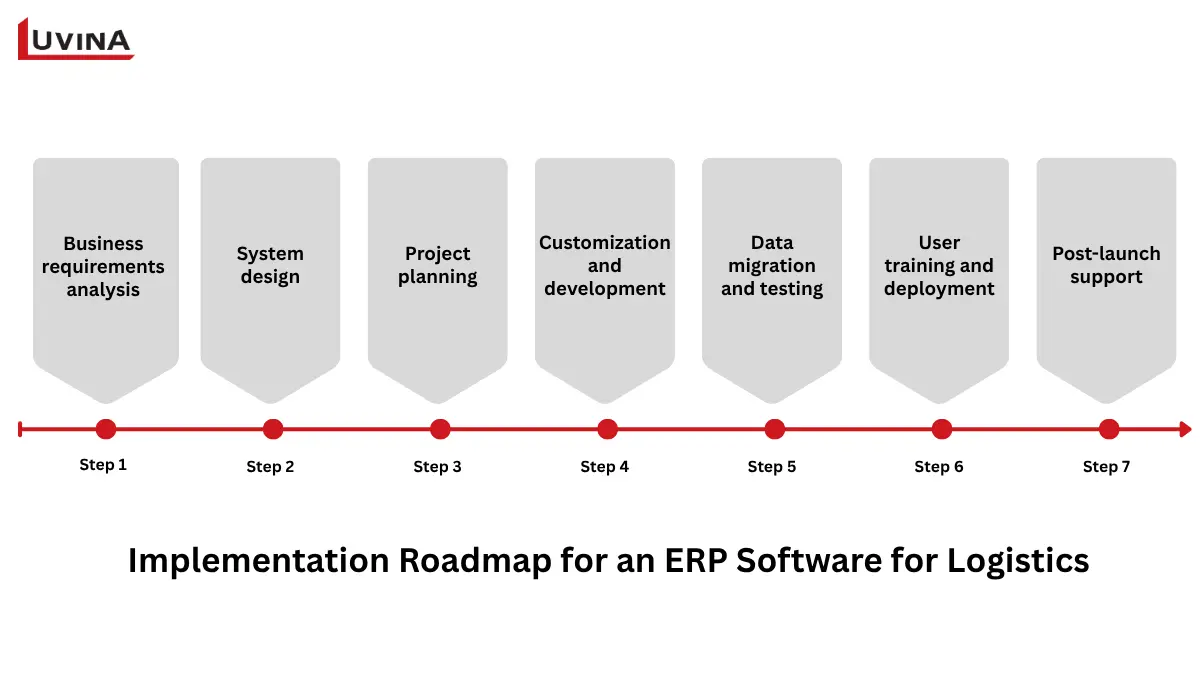

Implementation roadmap

Implementing an ERP system for logistics requires careful planning, cross-functional collaboration, and constant vigilance. An efficient plan makes sure that the system adds value and minimizes disruption. These are the steps for implementing an ERP system for logistics:

Step 1: Business requirements analysis

The implementation of an ERP system logistics begins by considering your current practices in detail. Identify the processes that exist currently, the issues with those processes, and what the potential benefit of the ERP system would be.

Recording company processes and pain points, like data input or delays in tracking shipments and describing what your future success might look like, all contribute to this stage. When as much involvement as possible from key stakeholders occurs at this point, an ERP system is better able to meet the particular needs of each function and grow sustainably.

If internal resources are limited, the selection process to pick an experienced logistics software development service provider should be conducted in this step too.

Step 2: System design

Design the ERP system for logistics based on the operational structure of your company once the requirements are understood. This includes determining the ERP design, user interface, and integration techniques with other systems. The team also chooses the appropriate technology stack during this phase to guarantee performance and compatibility.

Ensuring the system is user-friendly and able to handle logistic issues, including warehousing management and transport control, depends on the design stage, which is thus extremely important.

Step 3: Project planning

During this step, a complete implementation plan for the ERP system for logistics is put together. This details the deliverables, scope, and deadlines for all phases of the project. Additionally, budgeting, planning, resource planning, and risk management approaches are constructed to guide the project properly and keep it on track.

Because we will have established clear goals, scope and objectives, the implementation process will be more structured and measurable, reducing the possibility of cost overruns or delays for the logistics company.

Step 4: Customization and development

After planning, developers customize the ERP system to match business processes. This covers setting the ERP environment, setting up modules, creating business rules, and linking it with current systems, including warehouse management or accounting tools.

During this stage, security settings, processes, and access permissions are changed to guarantee compliance and data security. Before installation, testing environments are set up for validation as well.

Step 5: Data migration and testing

One of the most fragile phases in deploying ERP systems for logistics is data migration.

- – To avoid errors or data loss, legacy data must be cleaned, standardized, and moved in carefully phased stages.

- – To verify the ERP operates as expected, the team conducts multiple rounds of testing – functional, performance, and security.

- – Before the system goes live, key personnel conduct user acceptance testing (UAT) to confirm it meets all logistical requirements.

Step 6: User training and deployment

Without adequate training, no ERP system for logistics project works. Preparing user manuals, holding training courses, and making sure teams can totally utilize the new ERP features are all part of this stage. Pilot testing may be carried out before the formal go-live to handle last-minute modifications.

Once ready, deployment follows the project schedule with rollback mechanisms already in effect. Early operational weeks are supported to ensure a seamless change.

Step 7: Post-launch support

Post-launch support is vital once the ERP system goes live. This stage centers on performance improvement, user feedback gathering, and system monitoring. Technical teams roll out crucial fixes or updates and address any problems swiftly.

Regular assessments assist in spotting chances for enhancement and extra feature deployment. Long-term maintenance guarantees that the ERP system for logistics keeps up with corporate expansion and market developments.

Conclusion

The way logistic firms run is being changed by digital transformation; hence, remaining nimble and competitive depends on putting an ERP system for logistics into use. Controlling data is not only about that. It’s about developing a linked ecosystem whereby every item, transaction, and resource travels in harmony.

At Luvina, we help logistics companies turn ERP from a complex project into a practical growth solution. Our team provides end-to-end ERP services, including:

– ERP consulting: Technology stack choice, solution design, and business requirements analysis.

– ERP implementation: Post-launch support, testing, integration, customization, and system design.

Backed by more than 20 years of practical experience, we guarantee your ERP system for logistics is reliable, scalable, and perfectly matches your operational objectives.

Looking to simplify and strengthen your logistics operations? Book a free ERP consultation with Luvina to modernize your logistics operations.

Resources

- https://www.itransition.com/erp/logistics

- https://www.linkedin.com/pulse/erp-logistics-industry-transforming-supply-chain-efficiency-yz4of/

- https://quickdiceerp.com/blog/erp-solutions-for-logistics-key-features-benefits

- https://www.halsimplify.com/knowledge-center/erp-system-logistics-management-transformation#challenges-in-implementing-erp-for-logistics

- https://www.astracanyon.com/blog/top-erp-systems-for-manufacturing#syspro-erp

- https://www.linkedin.com/pulse/erp-logistics-industry-transforming-supply-chain-efficiency-yz4of/

- https://msdynamicsworld.com/blog-post/top-11-logistics-erp-software-solutions-us-businesses-2025

- https://havi.com.au/blog/erp-logistics#top-5-erp-systems-for-logistics-companies

- https://www.itransition.com/erp/logistics

- https://www.siriglobaltech.in/blog/logistics-erp-implementation-guide.html

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter