The supply chain industry has its backbone in warehousing. However, this sudden growth of logistics brought many complications to modern warehouses. It is here that AI in warehousing started finding its place. Artificial intelligence is bringing a change in many industries, and warehousing is no exception.

A survey conducted by Deloitte found that 38% of logistics companies are currently implementing automation and robotics solutions in their operations processes to liberate the workers for more strategic tasks. So, what does AI bring along in terms of benefits to warehouse management, and what are the future trends of this technology? Let’s find out from the article below.

Benefits of AI in Warehouse Management

If businesses know how to leverage the superior capabilities of AI in warehousing, they can manage warehouses more efficiently and safely while reducing waste and saving costs. Following are some of the major benefits of utilizing AI in warehouse management.

1. Improved inventory accuracy

AI warehouse management applications help collect data from multiple sources, often from IoT devices like barcode scanners, RFID tags, etc. These sensors display real-time warehouse activities, allowing businesses to track asset locations and inventory levels and gain valuable insights into process bottlenecks. In that light, with better visibility, a business would get to make proactive decisions to accelerate the solving of problems and improve operational efficiency.

Particularly, with the help of AI warehouse automation, employees can be freed from tedious and time-consuming tasks while eliminating risks related to manual data entry. In addition, AI can automate data analysis and provide timely insights for businesses.

2. Real-time operations optimization

One of the strengths of AI in warehouse management is its ability to constantly evaluate and adjust. This technology continuously analyzes data from sensors, scanners, and other data sources to gain insights into worker movements, equipment status, and inventory items. Based on this information, I will spot inefficiencies and bottlenecks in no time and suggest quick solutions right on the spot in real-time, ultimately making workflows smoother.

3. Predictive analytics

AI is considered one of the most suitable technologies for warehouse management due to its analytical abilities. Having clear insight into all the activities that are involved within a storage network, AI leads decision-making processes and provides insight, suggesting strategies that will help in supporting your sales plans. This would result in an optimization of workforce planning, organizing inventory, and equipment maintenance in real-time.

4. Inventory demand forecasting

Although AI doesn’t inherently understand what your inventory is or the demand it fulfills, it can generate useful demand forecasts based on the data you provide from various feeds. Today, businesses can use AI to analyze historical data, market trends, and many other factors that might influence accurate demand forecasts. AI-assisted demand forecasting helps warehouses fine-tune supply chain processes, anticipate demand changes, and make smart decisions related to purchasing, shipping, and inventory management.

5. Predictive maintenance

Another application of AI in warehouse management relates to equipment. With sensors and monitoring systems, AI can predict with accuracy equipment failures and provide maintenance needs in real time. Modern machines, in most instances, have sensors that give AI streams of information relating to the performance of equipment, warehouse conditions, and usage patterns, among others.

With this information, AI continuously observes the performance and will give comprehensive insights to companies on when to schedule maintenance for machinery life extension, thereby preventing accidents that may be caused by malfunction. AI minimizes warehouse downtime, saves money on maintenance, and ensures full performance of all the machinery and infrastructure involved while minimizing worker accidents.

6. Ensuring safety

AI in warehouse automation ensures a highly safe working environment. For example, AI can handle real-time monitoring, safety analysis, worker training, automatic alerts, and interventions. If data analysis helps businesses identify potential issues, continuous monitoring allows you to catch and mitigate unavoidable problems. Moreover, the presence of AI reduces the need for manual labor, which means fewer accidents since workers are less exposed to risky situations.

The Future Trends of AI in Warehouse Management

The logistics industry is entering a new era. As AI in warehousing is applied more effectively, the supply chain will undergo a complete transformation. Below are some key trends of data warehouse AI that are predicted to play a crucial role in changing this industry.

1. Computer Vision for Inventory Management

By automating processes like tracking, quality control, and safety monitoring, computer vision technology has been and will continue to significantly transform inventory management. This technology involves using cameras and AI to inspect and identify items, allowing businesses to track inventory in real-time without the need for manual management. Instead, computer vision systems can scan QR codes and barcodes or recognize products by shape to quickly and accurately control inventory, reduce human error, increase operational speed, and improve data reliability.

Additionally, computer vision systems can detect defective or abnormal products with high precision, ensuring that only items meeting standards are shipped. This leads to greater customer satisfaction and reduced return rates due to errors. With the support of AI data warehouse, improvements through computer vision also monitor warehouse environments to identify potential hazards, such as unsafe worker actions or obstacles in pathways, to prevent accidents and create a safer work environment.

While there are still many concerns about computer vision technology and privacy, the contribution that such technologies bring about in enhancing accuracy and safety in warehouses is undeniable. Moreover, computer technology can easily combine with human labor where these technologies enhance the abilities of workers, rather than taking their place. Consequently, a more efficient, safe, and harmonious work atmosphere will be presented.

2. Robotics and Automation

The integration of AI in warehousing, coupled with the use of robots and automation, is a major step toward enhancing warehouse operations and accuracy. Today, in smart warehouses, robots carry out various activities ranging from picking and packing to the movement of goods. This automated process not only accelerates operations but also diminishes human errors and ensures that orders are accomplished in a far more accurate manner.

The systems operate in various environments, with lots of care in handling many types of products. The robots are thus very helpful during the processing of several items because they adapt fast to operations; they can even work at any time of the day without rest for the same purpose of ensuring that productivity at the warehouse has been remarkably increased without any need for time breaks like humans.

Although some believe that the trend of robotization in warehouses will lead to job loss for workers, the positive side is that robots and AI warehouse management will free warehouse staff from repetitive and physically demanding tasks, allowing them to focus on more creative and strategic duties. Besides, the application of AI in warehouses and applications to the robots will also result in the development of jobs in the programming, maintenance, and supervision of the robots, enhancing the skilled labor force.

3. Machine Learning and Predictive Analytics

Machine learning and predictive analytics are two of the latest emerging technologies that have important roles in reinventing inventory management by increasing the accuracy of forecasts and making business decisions smarter. AI data warehouse, especially, performs deep analysis on large volumes of data for patterns and trends that human eyes can’t catch using historical data. This lets businesses estimate their need for the future, optimize inventories, and predict disruptions in the supply chain.

Data-driven and predictive approaches create an optimum level of inventory, reduce overstock or risks of stockouts, and ensure that resources are utilized efficiently. In addition, predictive analytics plays a very important role in the maintenance of warehouses. AI in warehouse management can predict equipment failure even before this happens, thus enabling businesses to schedule the maintenance needed to minimize downtime in operation and extend equipment life, hence ensuring that the warehouse works to full capacity.

Some would argue that the deployment of those technologies initially requires a high cost. Long-term, with increased ROI, it will prove that the initial investment in it is well worth it.

How to Implement AI in Warehousing?

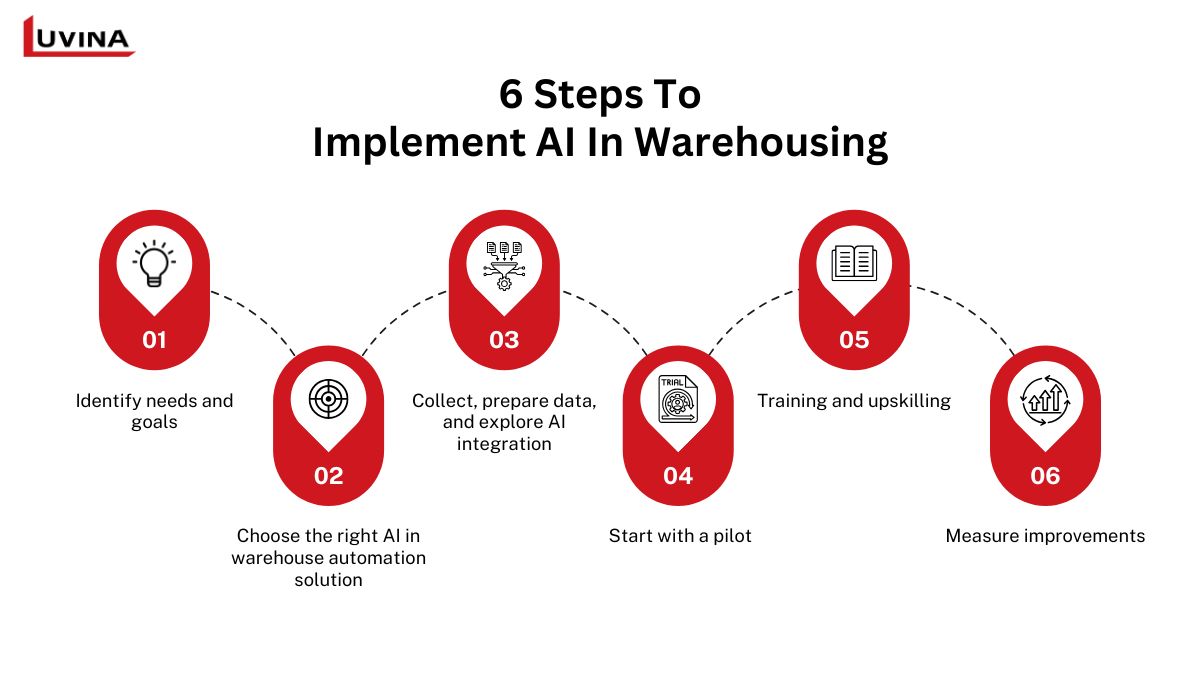

To implement AI in warehousing, we suggest the following detailed step-by-step process:

Step 1: Identify needs and goals

Start by identifying the specific challenges you want to solve, the goals you want to achieve, and how you will adjust AI to your current processes. Are you looking to optimize inventory management, improve safety, or enhance order fulfillment? Clearly defining your goals from the beginning will help you measure the success of the project and choose the right AI warehouse automation solution.

Step 2: Choose the right AI in the warehouse automation solution

One of the most important steps in implementing an AI data warehouse is choosing the solution that best fits your business model. The right solution will provide the most benefits at the lowest cost and time. Research the available AI technologies and select the ones that meet your needs and goals. When selecting an AI solution, consider factors like your project budget, existing infrastructure, and required technical expertise. Being a small business owner, you don’t need a very complex solution, but if you plan to scale up in the coming years, choose a solution that can scale up with you.

If you have difficulty finding or selecting AI data warehouse solutions, seek support from AI vendors and consultants.

Step 3: Collect, prepare data, and explore AI integration

First, make sure that the correct data infrastructure is put in place to capture, store, and process information that will be required by the various AI solutions. This may include integrating existing systems, deploying new sensors or cameras, cleaning data, and validation of data quality. In some cases, training of staff for the management of those technologies may also be necessary. The better you prepare your data, the easier the implementation of AI-automated warehouses will be, causing minimal operational disruption.

Step 4: Start with a pilot

Before the full deployment of AI, you can start with a small pilot project to test out your selected AI solutions in a controlled environment. This would ensure you find problems, adjust your approach, and show stakeholders the value of applying artificial intelligence in data warehousing. Once the pilot goes well, you will gradually deploy AI across the whole warehouse.

Step 5: Training and upskilling

AI in the warehouse will make the tasks easier for the participants involved, but widely implementing this technology is not easy. Equipping your workforce with the skills necessary to manage, operate, and maintain these systems is required for successfully implementing AI in warehousing. The time and effort invested in training will pay dividends as your employees will be able to embrace the technology and adjust their ways to meet the changing needs of a modern warehouse.

Some employees might fear AI will take their jobs, but here is where clarification must be made: it’s not taking their jobs, it’s just changing them—you can shift the workers to more technical expertise roles, hence more problem-solving, while AI takes over all the repetitive and time-consuming tasks.

Step 6: Measure improvements

For maximum efficiency in the warehouse, measurement and assessment should be performed all the time. You need to compare some key metrics before and after the implementation of AI in warehouse management to confirm that the solution is effective. The above evaluation will also provide you with a view of the bottlenecks or areas where AI does not seem effective yet, due to which you can make a number of adjustments and improvements.

Conclusion

The use of AI within warehouse management will be the most pivotal element in changing the logistics industry since the integration of AI in the warehouses will enable more proficient and correct management of warehouses by increasing their resilience. Despite challenges within technology, cost, and training the workforce, AI will still remain one of the key technologies shaping the future operations of warehousing.

If you aim to optimize warehouse performance and gain a competitive edge in the market, adopting AI is essential. Are you ready to implement AI in warehouses? If the answer is yes, contact Luvina for detailed support and consultation.

Related Posts:

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter