Traditional warehouse management solutions are failing as supply chains get more complicated and cost-cutting demands grow. For example, in industries like retail, F&B, and manufacturing, where SKU counts are high and fulfillment timelines are tight, traditional WMS often can’t keep up with real-time visibility or custom workflows. More businesses are hence adopting a custom warehouse management system, a solution designed to fit their specific operational needs and processes.

This post will cover what a custom WMS is, why it is becoming so important in the modern logistics environment, and how you might create one that promotes automation, lowers expenses, and scales together with your company. Beginning here, if you want to future-proof your warehouse activities.

What Is a Custom Warehouse Management System?

Designed to improve every step of warehouse operations – from receiving and storing goods to picking, packing, and shipping – a custom warehouse management system is a tailored software solution. Unlike generic WMS solutions, a customized WMS software is created to suit a company’s particular processes, storage methods, and operational demands.

The main objective of any Warehouse Management System (WMS) is to automate warehouse operations, therefore enhancing accuracy, lowering costs, and reducing manual effort. By providing capabilities and interfaces tailored to your warehouse’s real-world circumstances, a custom solution goes beyond this. Usually, these systems provide companies with a unified and extremely flexible management setting by merging flawlessly with external tools like ERP, shipping, or inventory platforms.

Off-the-Shelf WMS vs Custom-Built: Which Drives Better ROI?

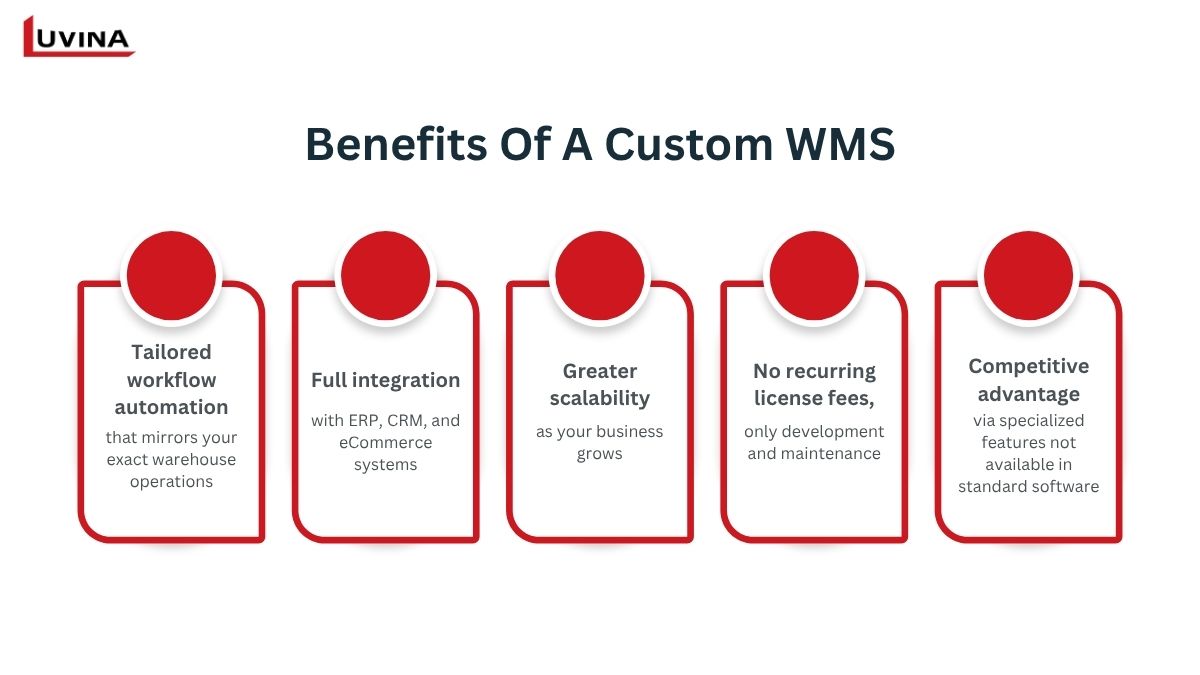

Many businesses begin with pre-built WMS platforms. But over time, they realize that these generic systems can’t fully adapt to their changing needs. Meanwhile, a custom WMS offers:

- Tailored workflow automation that mirrors your exact warehouse operations: A custom WMS developed around your specific warehouse structure and processes removes the need to change your activities to match a stiff system, from managing perishable goods, specializing in yard logistics, or advanced reporting.

- Full integration with ERP, CRM, and eCommerce systems: A custom WMS can be developed to integrate directly with your existing software landscape, and therefore offer complete integration with ERP, CRM, and eCommerce systems. This closer connection eliminates data silos, contributes to communication across departments, and gives real-time updates across warehousing, sales and customer service teams.

- Greater scalability as your business grows: A customized WMS can grow as you grow (adding new warehouse clusters, adding new SKUs, or adding sales locations). There’s no restriction imposed by the limits of a prebuilt platform, and as your needs change, you will never have to go through a massive system update process.

- No recurring license fees, only development and maintenance: Off-the-shelf systems often include yearly license and subscription expenses for every user or module. Investing in development and maintenance with a custom solution allows you to get total ownership of the system and removes monthly charges.

- Competitive advantage via specialized features not available in standard software: This helps validate its ability to handle real-world tasks such as fulfillment and inventory synchronization. Such specialized features are just not contained in one-size-fits-all software.

Key Features of a Custom Warehouse Management System

A solid custom warehouse management system isn’t only about inventory organization. It’s about providing you with total control, visibility, and efficiency on every operational aspect of your warehouse. Here we describe the basic features of a robust, tailored warehouse management system:

| No. | Features | Description |

| 1 | Real-time inventory tracking | Provides live visibility into stock levels, movements, and locations across multiple warehouses, reducing errors and preventing stockouts. |

| 2 | Barcode/RFID integration | Enables fast, accurate scanning and tracking of items using barcodes or RFID tags, supporting automation and minimizing manual entry mistakes. |

| 3 | Multi-warehouse & location control | Centralized control over inventory across multiple warehouse locations, enabling efficient transfers and location-specific stock visibility. |

| 4 | Advanced picking methods | Supports wave, batch, zone, and discrete picking to streamline fulfillment processes and reduce labor costs. |

| 5 | Customizable dashboards & reports | Offers configurable dashboards to monitor key performance metrics (KPIs), generate automated reports, and visualize real-time warehouse performance data. |

| 6 | User role management | Granular control over user permissions and access levels, ensuring data security and operational accountability. |

| 7 | API & ERP Integration | Seamlessly connects with ERP, CRM, and eCommerce platforms to unify workflows, eliminate data silos, and enable real-time data syncing across systems. |

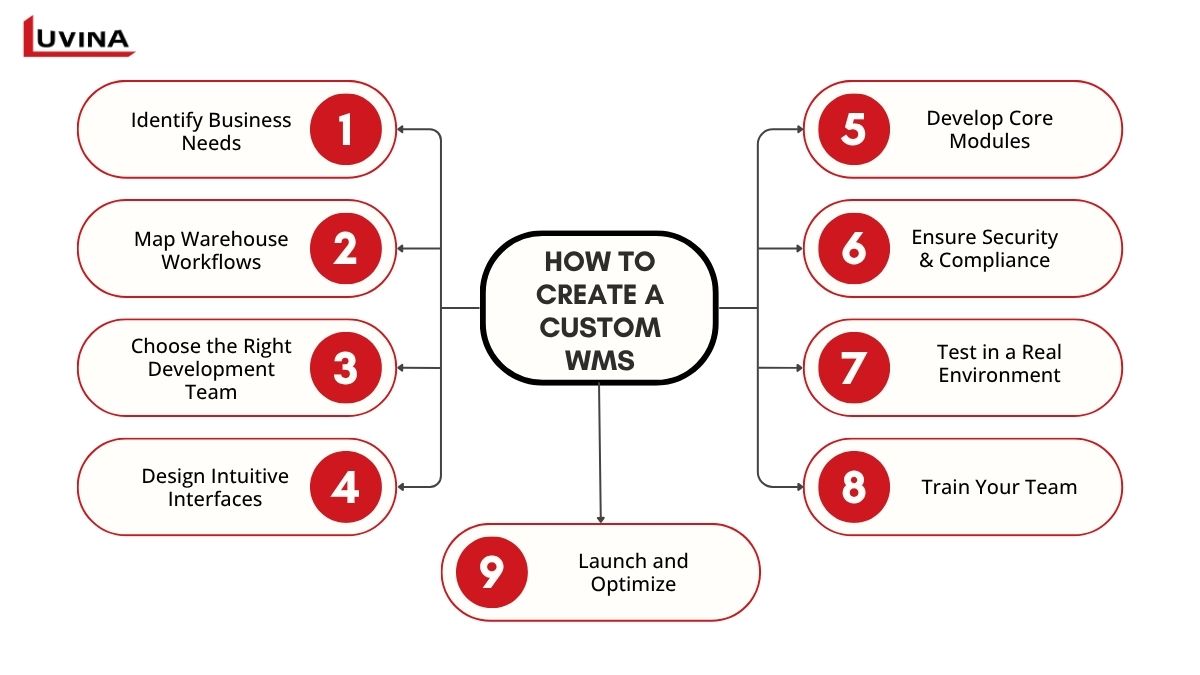

How to Create a Custom WMS: Step-by-Step

Creating a custom warehouse management system calls for meticulous planning. Here we will go over the main stages of the development process.

1. Identify Business Needs

To begin, identify the specific challenges your warehouse is facing. This might include issues like incorrect inventory, expedited order turns, or insufficient integration with existing systems. Clearly define the goals you want your custom warehouse management system to achieve when implemented. This could include eliminating manual errors, improving visibility of your stock, or simplifying communication across other departments.

2. Map Warehouse Workflows

Now that your goals are prepared, the subsequent step is to dissect your warehouse. This means explaining every major process – receiving, putaway, picking, packing, shipping, returns, and inventory counts – to understand the relationship between processes and potential slowdowns or inefficiencies.

Mapping these processes gives you a solid basis for planning user interfaces and system logic. Moreover, it enables your development team to create a scalable, easy design that enables flawless integration with current platforms, including ERP or e-commerce systems.

3. Choose the Right Development Team

Choosing the best team is vital to the development of a dependable and expandable bespoke warehouse management software. You must choose whether to build in-house or work with an outside software company. Outsourcing calls for a staff with demonstrated knowledge of logistics and warehouse technology since they will better grasp the subtleties of supply chain activities.

Whatever route you take, be sure the developers can provide a flexible, safe, and fully integrated solution that matches your long-term company objectives.

4. Design Intuitive Interfaces

Your WMS’s performance can be determined by a well-designed interface. Concentrate on developing simple, user-friendly screens that warehouse staff may negotiate with little instruction. This entails designing layouts for several user roles and making sure the system runs smoothly on mobile devices or scanners. Beyond increasing output, an intuitive interface lowers the risk of human error during quick warehouse operations.

5. Develop Core Modules

The core functional components of every custom warehouse management system define it. Start by building the essential modules, including inventory management, inbound and outbound order processing, and real-time reporting. These basic characteristics guarantee effective daily operations.

From here, you can enhance precision and efficiency by adding more beneficial advanced functions like barcode scanning, voice-picking technology, or AI-based demand forecasting. The goal is to build a flexible system that is designed to grow with your company.

6. Ensure Security & Compliance

As your warehouse system handles sensitive business and customer data, securing that information is non-negotiable. Implement robust security measures such as role-based access control, data encryption, and secure API protocols to prevent unauthorized access or data breaches.

Additionally, your customized WMS software should comply with relevant industry regulations (GDPR, ISO standards, or specific logistics certifications, etc.) to ensure legal and operational reliability.

7. Test in a Real Environment

Validating your WMS’s performance in actual warehouse circumstances is vital before rolling it out at scale. Start by installing the system at one site or running it in parallel with your current tools. This lets you judge how well it manages actual processes ranging from order fulfillment to inventory updates.

Early testing aids in the detection of problems before complete implementation, therefore lowering the possibility of daily interruptions. Focus on testing for system stability, data accuracy, and easy integration with ERP or eCommerce systems.

8. Train Your Team

The efficiency with which your employees can utilize a WMS determines its successful application.

- Offer thorough training plans customized for every user type.

- To guarantee that everyone knows the functionality and best practices of the system, employ role-specific handbooks, interactive demos, and clear onboarding materials.

Well-trained teams not only react more quickly but from day one also help you to get your new procedures operating at peak efficiency and accuracy.

9. Launch and Optimize

After testing and training, it’s time to roll out your custom warehouse management system. But gradual deployment is key. Start with a smaller warehouse or a specific department to monitor real-time performance and gather feedback. Track key metrics, identify bugs or inefficiencies, and make adjustments as needed.

You can include improvements in this phase, and it will help you refine processes, as well as help ensure the system continues to align with business needs as it expands across the organization.

How Much Does It Cost to Build a Custom WMS?

The price of a custom warehouse management system depends greatly on your demands, features, and development processes.

You will often spend:

- – WMS for a small business: $25,000 and $50,000.

- – WMS for a mid-sized business (with several warehouses): $70,000 and $150,000.

- – A business-level WMS incorporating an ERP: $200,000+

Although the initial cost might appear high, better inventory visibility, increased efficiency, and fewer operational errors cause several companies to get a return on investment in one to two years.

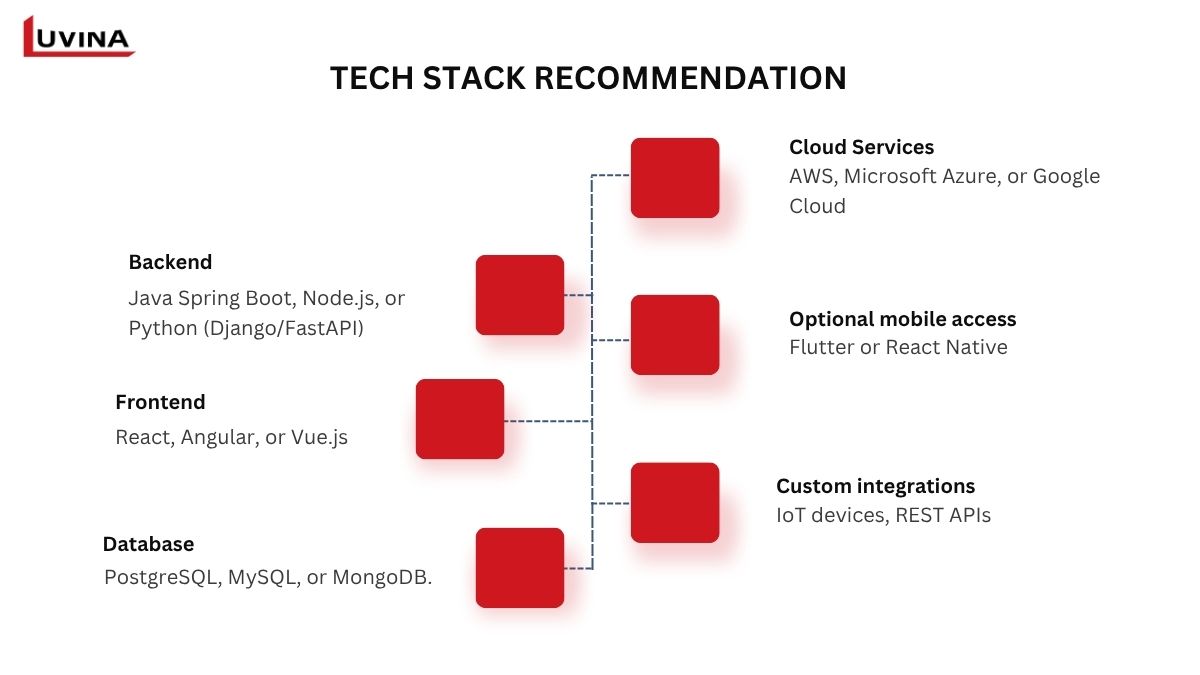

Recommended Tech Stack for Custom WMS Development

Developing a custom warehouse management system demands selecting solutions that can smoothly adjust to your unique warehouse processes and grow with your company. Here is a frequently used stack recommended in the successful development of custom-built WMS solutions:

- Backend (Java Spring Boot, Node.js, Python): Ideal for building scalable, high-performance APIs and managing concurrent warehouse operations.

- Frontend (React, Angular): Enables fast, responsive UI for dashboards and mobile terminals.

- Database (PostgreSQL, MongoDB): Reliable for structured inventory data and flexible schema for tracking logs.

- Cloud (AWS, Azure): Ensure uptime, scalability, and real-time access across regions.

- Mobile (Flutter, React Native): Deliver seamless mobile UX for warehouse staff using handheld scanners or tablets.

Contemporary warehouse management system architecture relies heavily on custom integrations. Integrating IoT devices – whether it’s smart forklifts, environmental sensors, or RFID-enabled devices – can be an exciting enhancement. We find that advanced features that improve automation and increase real-time visibility across the warehouse erroneously mix two acclimatizing concepts. Using REST APIs, you could even integrate with third-party platforms, sync with ERP and eCommerce systems, or utilize Electronic Data Interchange (EDI) for B2B transactions.

>> Also read: AI in Warehouse Management: Key Benefits & Use Cases

Why Choose Luvina for Your Custom WMS Development?

Creating a top custom warehouse management system calls for a partner able to transform logistical problems into simplified digital solutions. This explains why you need Luvina as a technological ally. With over 20 years of experience and 100+ logistics and warehousing projects delivered globally, Luvina helps companies reduce inventory errors by 40%, improve picking efficiency by 30%, and cut training time for warehouse staff by 50%.

For companies in manufacturing, retail, wholesale… our specialty is designing and implementing custom warehouse management system solutions that improve general warehouse efficiency, automate procedures, and boost visibility. We use deep domain knowledge combined with sophisticated technology stacks to create future-proof WMS platforms. Every system is designed to fit your objectives, storage demands, and workflows.

Included in our services are:

- – Custom WMS creation: Customized systems to simplify warehouse processes across divisions

- – WMS mobile apps: From anywhere, real-time inventory control and delivery tracking

- – Smooth connection with ERP, RFID, barcode systems, and more: WMS integration services

Luvina provides the technical accuracy and industry understanding you need, whether you’re starting from scratch or enhancing an already in-use system. Want to explore how a custom WMS could transform your warehouse? Schedule a free consultation with our team today.

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter