One game-changing development that influences how modern factories operate is the custom manufacturing execution system. Over 74% of manufacturers making digital transformation investments prioritize MES integration as a major driver of productivity and cost effectiveness, according to a new Deloitte poll.

This comprehensive 2025 manual will guide you from selecting the appropriate strategy to accurately budgeting. It covers everything you need to know about custom MES, from seamless integration to supplier evaluation. Whether you are a tiny factory trying to maximize daily operations or a multinational company targeting end-to-end visibility, this resource will guide you to make certain, future-proof decisions.

What is a Custom Manufacturing Execution System

A manufacturing execution system (MES) is designed to track, manage, and optimize manufacturing processes in real time. It acts as a digital visualization of modern production. A basic MES allows transparency into production, and thus, allows better use of resources, quality, and efficiency, which is based between Enterprise Resource Planning (ERP) systems and shop floor equipment. It is an informational hub where the flow of accepted information from planning is based on execution, allowing producers to react quickly to changing circumstances.

A conventional MES has strong capabilities, yet its predetermined workflows may not always match perfectly with every factory’s individual needs. This is where a custom manufacturing execution system distinguishes itself.

A custom MES mirrors a manufacturer’s workflows, proprietary processes, and business goals. Unlike generic MES, it adapts to your processes instead of forcing adaptation. It guarantees that user interfaces, data integration, and reporting are tailored to be as operationally relevant as possible and thus avoids the ineffectiveness of a one-size-fits-all solution.

The following are the main distinctions between a custom manufacturing execution system and a typical MES:

| Features | Standard MES | Custome MES |

| Implementation | Fixed workflows, fast setup | Tailored design, longer setup |

| Flexibility | Limited customization | Fully adaptable to processes |

| Cost | Lower upfront cost | Higher cost, long-term ROI |

| Integration | Basic ERP/machine links | Deep ERP/PLM/QMS integration |

| Scability | Vendor-driven upgrades | Evolves with business needs |

| Control | Vendor roadmap dependent | Full ownership, self-managed |

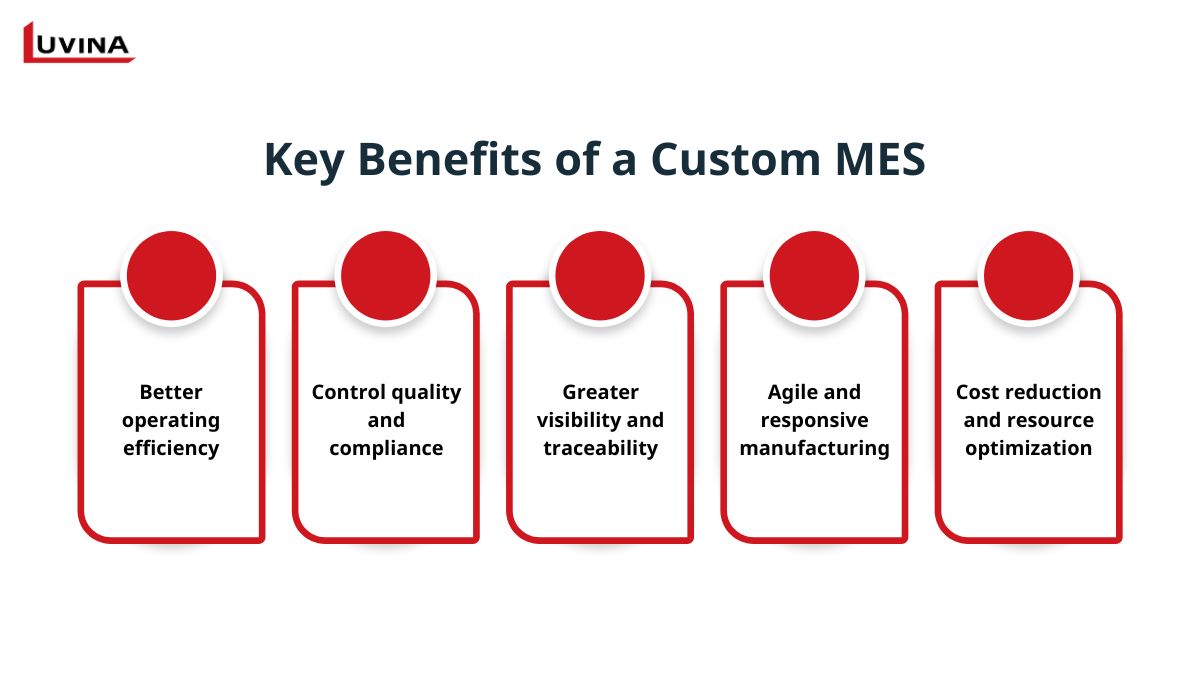

Key benefits of a custom MES software

Custom manufacturing execution system implementation enables manufacturers to obtain the flexibility and accuracy needed to improve their output performance. Core advantages are detailed below:

– Better operating efficiency: By automating data collection and simplifying workflows, a custom manufacturing execution system lowers manual errors and cycle times. Manufacturers may get greater throughput and increased productivity by carefully distributing labor, supplies, and machinery.

– Control quality and compliance: By coordinating quality checks and real-time monitoring, producers can immediately discover issues and take corrective action before defects become pervasive – this improves quality and compliance. In addition to minimizing rework and waste, it also serves to support compliance with stringent government regulations and industry standards.

– Greater visibility and traceability: A custom manufacturing execution system gives end-to-end visibility across the production line. Every material, batch, or item may be followed by managers in real time, therefore simplifying root cause analysis, speeding up problem resolution, and enabling continuous improvement efforts.

– Agile and responsive manufacturing: Real-time data exchange allows a bespoke MES to help producers rapidly modify schedules, processes, and resource use to satisfy shifting consumer expectations or market circumstances. This flexibility keeps fast-moving sectors competitive.

– Cost reduction and resource optimization: Investing in custom MES software helps to improve production planning and reduce inventory management by means of cost reduction and resource optimization. Cutting storage expenses, lowering work-in-progress (WIP), and getting rid of non-value-added operations help businesses to considerably reduce operating costs and increase profit.

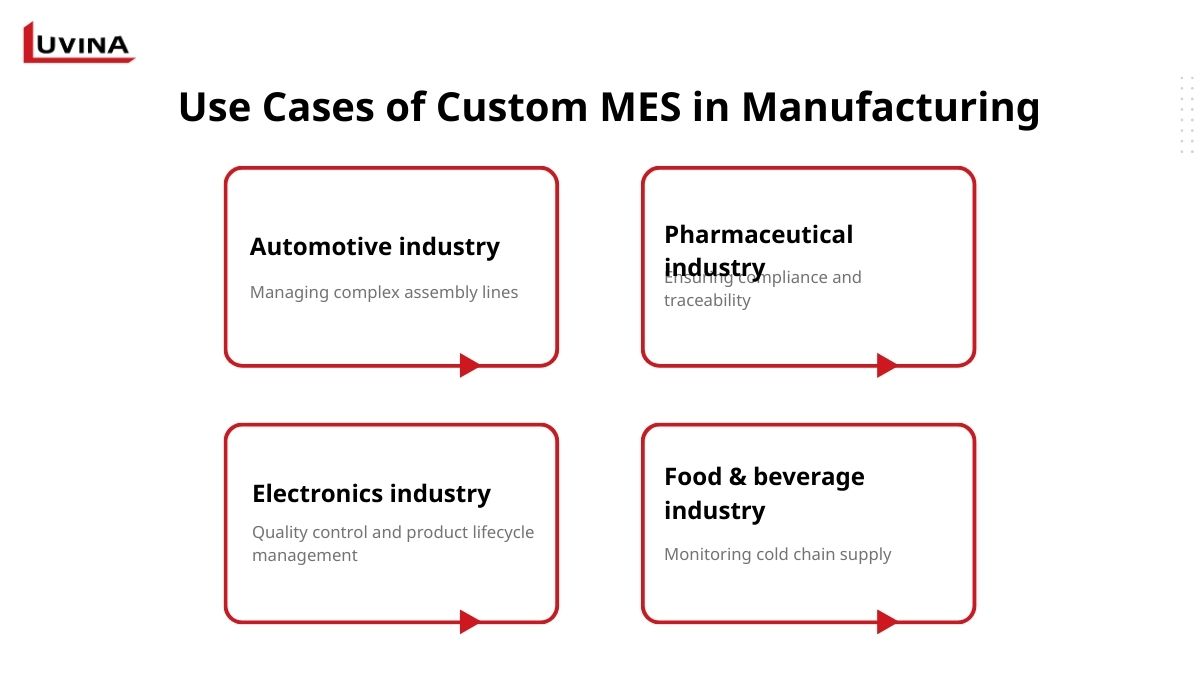

Use cases of custom MES in manufacturing

One kind of production environment does not restrict a custom manufacturing execution system; rather, it changes with the particular problems of every sector. Here are some real-world applications where a tailored MES offers clearly seen worth:

Automotive industry – Managing complex assembly lines

Automotive manufacturing demands hundreds of parts and really synchronised assembly procedures. A custom manufacturing execution system guarantees precise component tracking, harmonizes processes across various locations, and upholds quality inspections at every stage. This helps lean manufacturing methods, cuts time-to-market, and lowers mistakes.

Pharmaceutical industry – Ensuring compliance and traceability

End-to-end traceability, electronic batch records, and GMP requirements enforcement are all assisted by a custom MES. This guarantees that every medication can be traced back to its raw components and manufacturing history, therefore lowering compliance concerns.

Electronics industry – Quality control and product lifecycle management

Real-time defect detection, version control across product lifecycles, and traceability for guarantee and after-sales service are all made possible by a custom MES.

Food & beverage industry – Monitoring cold chain supply

Maintaining safety and freshness requires rigorous monitoring of storage and transportation conditions in food production. A custom MES tracks temperature, humidity, and handling over the whole cold chain, guaranteeing adherence to food safety standards and reducing spoilage. fintech expansion? Get in touch with Luvina right away to turn your API integrations into a competitive edge.

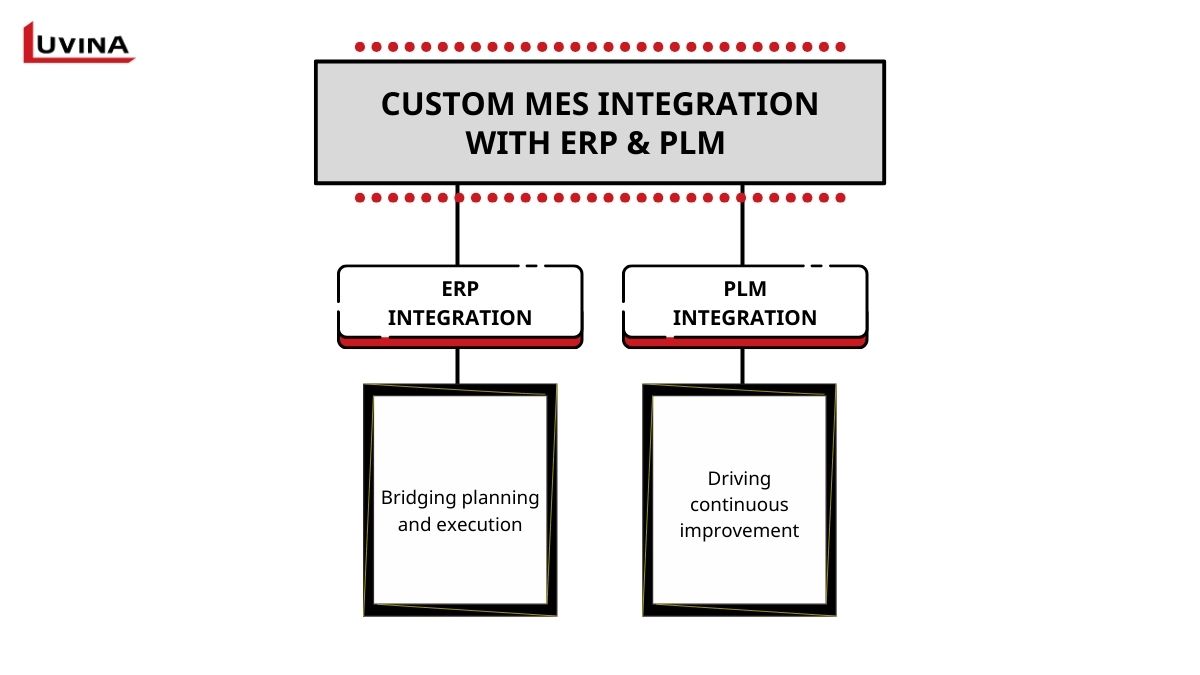

Custom MES integration with ERP & PLM

For contemporary producers, the worth of a custom manufacturing execution system rests in its capacity to engage with other company systems. MES turns into the core hub for visibility, cooperation, and decision-making throughout the company when incorporated with ERP and PLM, it transcends its role as a production management tool.

ERP integration – Bridging planning and execution

From order management to material planning and scheduling, ERP systems help to define what needs to be produced. A custom manufacturing execution system presents the missing link by revealing how those goods are made on the shop floor. This real-time feedback cycle guarantees that financial, supply chain, and operating data stay in sync, lowers trash, and boosts scheduling accuracy. The outcome is a more nimble company able to predict demand, maximize asset use, and provide goods quickly.

PLM integration – Driving continuous improvement

While PLM manages the product lifecycle, ERP focuses on planning. Combining PLM with a custom manufacturing execution system (MES) creates a digital thread linking empirical manufacturing data with design and engineering thinking. Improved tool design, less rework, and greater collaboration across the team assist transformational speed, reduced time-to-market, and reduced costs.

Greater MES-PLM integration will allow producers to realize real digital continuity, which contributes directly to smarter factories and continuous product evolution.

How much does a custom MES cost

The cost of a custom MES varies by company size, manufacturing complexity, and integration needs. For an “off-the-shelf” software system, you pay for the system and might incur some changes, but you have a contract that backs the use; for the most part, you certainly know the price of a software system. Customization on a custom MES includes development, changes to the baseline system going forward, and support going forward.

Expect mid-size companies to spend $375,000 – $600,000, commercial enterprises to spend $750,000 – $1,200,000. These figures are for the baseline systems, plus the additional layers needed in order to accomplish a successful deployment.

The significant cost components are: license or subscription, installation and configuration, onboarding and training, required hardware upgrades and infrastructure, ongoing support and upgrades, etc.

How to choose the right custom MES provider

Choosing the right partner for your custom MES is a critical decision. It impacts ROI, efficiency, and scalability in the long run. Since every manufacturer has different needs, your provider should not only fit your existing requirements but also aid your expansion in the future. These are the most critical elements to think about:

– Implementation timeline and cost: A few vendors offer cloud-based services that have lower upfront associated costs, sometimes resulting in a lower total cost of ownership. While on-premises projects often take more time and larger upfront project costs. A specific project timeline and accurate cost will help avoid surprises in costs and delays of expected results.

– Proven track record: Because your MES provider will manage mission-critical data, credibility is essential. Find a seller with a record of successful projects in your field and assess their credibility by reading client testimonials or case studies.

– Integration with ERP and other enterprise systems: Your strong custom manufacturing execution system should smoothly interface with your MRP, ERP, and IoT systems.

– Advanced reporting and analytics: Modern MES should include insights through dashboards, analytics, and business intelligence tools. These capabilities enable manufacturers to make data-driven decisions and achieve performance improvements at every level.– Scalability and flexibility: Your MES must change along with your business; therefore, it is important to choose a flexible, scalable MES. A flexible, configured platform assures that you won’t require a system change as you grow or implement new technologies.

Why partner with Luvina Software

Since 2004, the Vietnamese trusted IT consulting and software engineering firm Luvina Software has been specializing in designing and deploying MES solutions under ISO 9001. We offer quality and data protection through ISO 27001 certification. Our team, from need analysis and design to system integration implementation, user training, and ongoing support, can provide information systems in its entirety.

With Luvina’s knowledge, producers can have complete visibility of production, streamlined systems, and optimal decision-making. Our experts are here to help you if you’re prepared to maximise your company with a customised MES solution.

Ready to transform your factory with a custom manufacturing execution system? Contact Luvina Software for a free consultation.

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter