While the phrase “manufacturing inventory management system” can sound technical, it is, in fact, at the very nucleus of every successful factory floor. Consider walking into a production line floor where materials arrive exactly when needed, stock does not pile up, and customer orders are always completed on time and as promised. Nothing is a coincidence; everything about this environment is the result of proper inventory management, backed by technology.

In this article, we will examine a manufacturing inventory management system – what it is, what it is used for, and its potential value; we will consider the aspects (components, functions, protocols) of a manufacturing inventory management system; we will address some of the obstacles and issues with executing a manufacturing inventory management system; and finally we will share our thoughts on where we expect to be in 2025.

What is a Manufacturing Inventory Management System

Designed to assist producers in planning, monitoring, and managing materials as they progress through each stage of the manufacturing process, a manufacturing inventory management system helps them.

A manufacturing inventory management system works closely with production processes, unlike basic stock tracking tools. While real-time reporting and demand forecasting help financial accuracy, they serve as a control center linking sourcing, warehousing activities, and logistics.

Many modern producers use manufacturing inventory software to automate these chores. Real-time monitoring, automatic purchasing, and KPI tracking (such as turnover ratio or carrying cost) provide deeper insights for faster decisions. This is especially important in sectors like electronics, automotive, or food manufacturing, where material handling directly impacts profitability.

Fundamentally, a manufacturing inventory system is more about coordinating asset movement throughout the supply chain than just counting stock. Financial success and competitiveness of any manufacturing company depend much on finding a compromise between cost-effectiveness and consumer happiness.

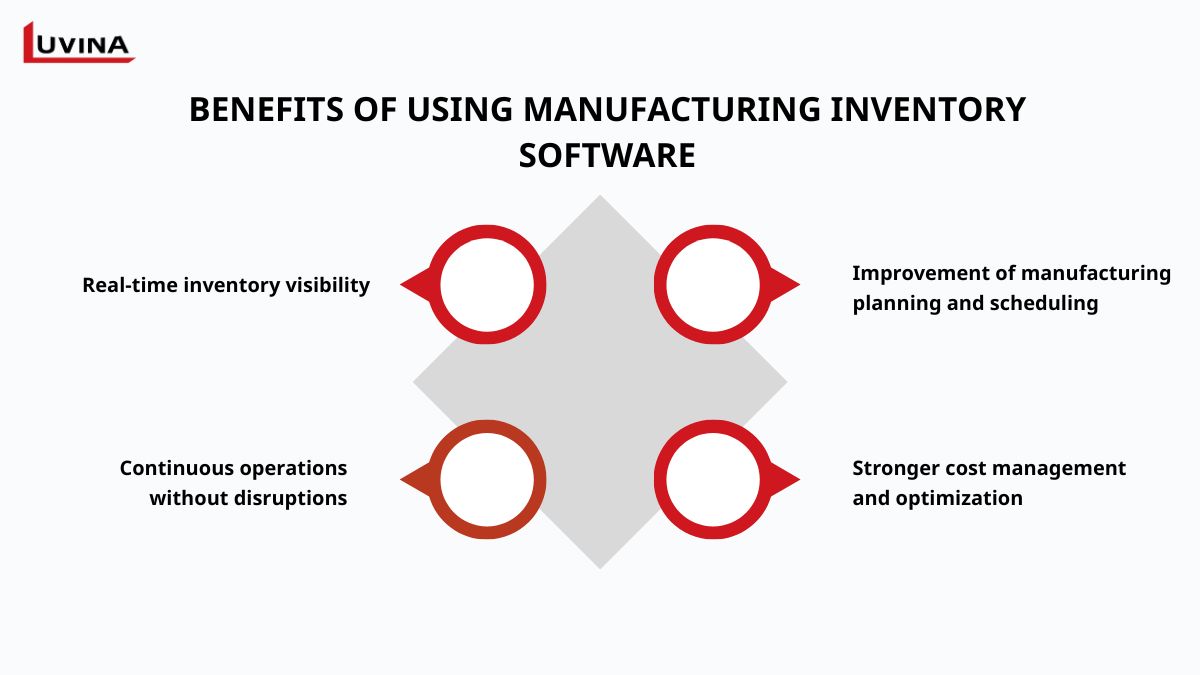

Benefits of using manufacturing inventory software

Manufacturers see obvious advantages to employing a manufacturing inventory management system – not just through simplifying operations but also through improved financial performance and quality of supply chain performance.

Real-time inventory visibility: Manufacturing inventory management systems give you timely views of your inventory levels across a variety of warehouses and lines of production. This can include your raw materials, work-in-progress, and finished goods – all available to you in real-time, helping to alleviate human error and extreme costs due to stock-outs or excess inventory.

Improvement of manufacturing planning and scheduling: Manufacturers can implement manufacturing and inventory management software in an effort to manage and balance materials availability, human capacity, and machine utilization together. Advanced scheduling software can manage this effort in an effective and efficient way to ensure production is completed, without delay, offering alternative solutions in the event of the occurrence of unforeseen events.

Continuous operations without disruptions: Modern manufacturing inventory software is designed with built-in High Availability (HA) and Disaster Recovery (DR). With real-time replication, cloud failover, and multi-region backups, it ensures that even during outages or data center failures, operations keep running and data stays protected.

Stronger cost management and optimization: Inventory management software for the manufacturing industry computes comprehensive expenses, including overhead, labor, and materials, therefore empowering better control. Additionally, tracking inventory turnover and holding expenses offers ideas to cut waste, maximize stock levels, and raise revenue.

Key features of manufacturing and inventory management software

At every level of the manufacturing cycle, a central hub called a manufacturing inventory management system provides visibility, automation, and correctness. Here are the fundamental qualities that render this technology indispensable:

| Features | Descriptions |

| Real-time tracking and barcode scanning | Barcode or RFID scanning updates inventory data immediately, guaranteeing every raw material, WIP item, or finished product is accounted for. |

| Automated purchase order generation | The system creates purchase orders automatically when stock levels go below previously established thresholds. |

| Lot and serial number tracking | The software facilitates batch and serial tracing for companies needing strong compliance or traceability. Where recalls and quality inspections call for accuracy, in industries including food, pharmaceuticals, or electronics, this feature is needed. |

| Streamlined order processing | Businesses have complete order lifecycle visibility from order definition to fulfillment. |

| Cost monitoring and reporting | Supports Activity-Based Costing (ABC) for precise cost allocation, and integrates with ERP systems (SAP, Oracle, D365) for consolidated financial reporting. |

| Mobile and cloud-based accessibility | Mobile apps from contemporary systems, like inventory software for a manufacturing company, enable real-time connection between managers, technicians, and warehouse employees. Support of agile decision-making comes from cloud integration, which lets teams share and update data from anywhere. |

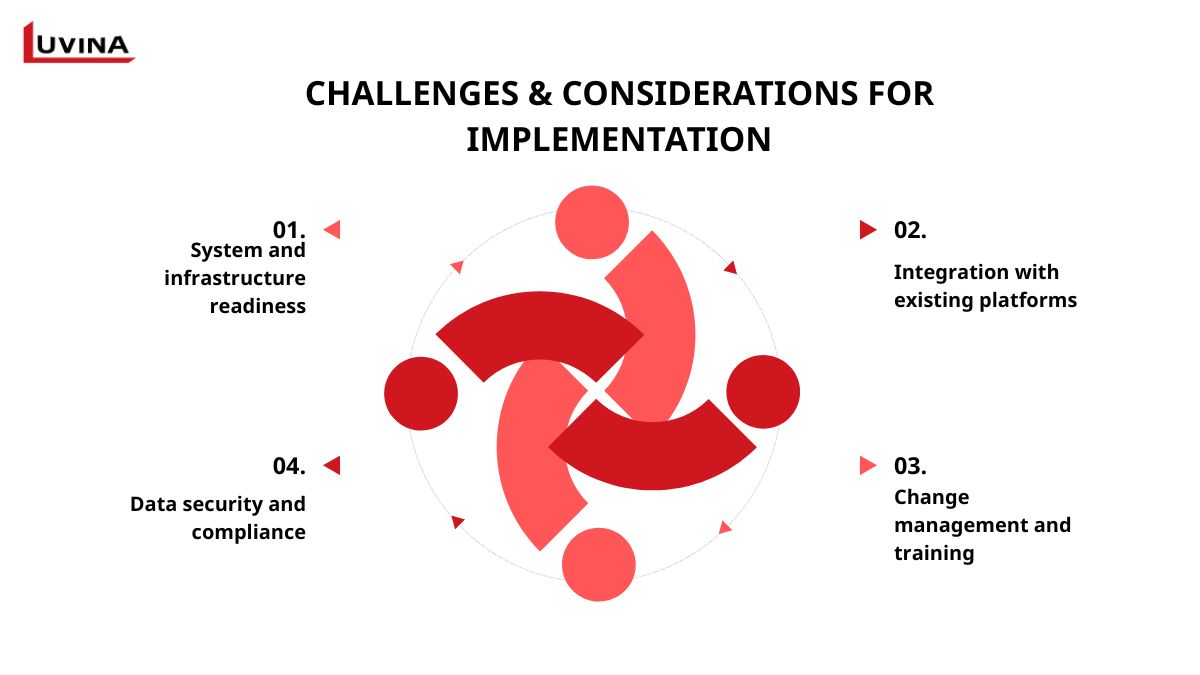

Challenges in implementing a manufacturing inventory system

Though deploying a manufacturing inventory management system presents difficulties that need thorough planning, it can provide significant efficiency advantages. Companies run the danger of cost overruns, downtime, or constrained end-user adoption without adequate preparation.

System and infrastructure readiness

Hardware that is current, dependable servers, and robust network connectivity are often required by a new manufacturing inventory management system. To prevent performance bottlenecks, companies must confirm that their infrastructure can accommodate mobile device support, remote access, and heavy data processing.

Integration with existing platforms

Rarely run on one system are contemporary processes. Whether the solution seamlessly works with shop-floor applications, accounting systems, and ERP platforms determines successful adoption. Poor integration strategy causes data silos; strong synchronization and ETL procedures guarantee real-time, uniform visibility throughout the supply chain.

Data security and compliance

In addition to providing inventory control software manufacturing, part of the job is to handle sensitive operational and financial data. Manufacturers should put in place tight security, such as role-based access, frequent system audits, and encrypted connections. Especially for industries that require strict traceability, compliance with laws and industry standards is vital.

Change management and training

If staff are not properly trained or resistant to change, even the best factory inventory management software can fail. Clear communication, phased rollouts, and thorough onboarding systems enable teams to adjust, minimizing errors and maximizing the worth of the system.

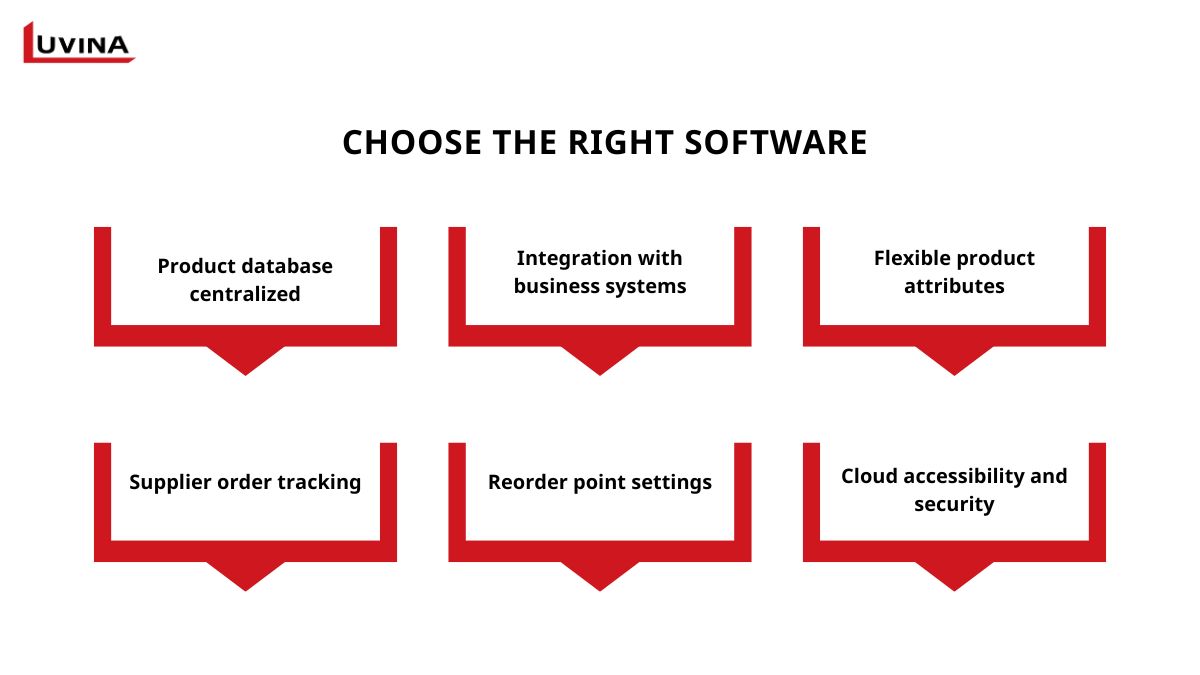

How to choose the right software

Selecting the proper solution is equally important as deciding to implement a manufacturing inventory management system at the outset. Your level of staff cooperation, the efficacy of the process, and your control of inventory levels will all be influenced by you. When assessing a solution, you should give careful consideration to the following:

Product database centralized: The program ought to let you keep your whole product catalog in one location, hence avoiding duplicate entries and guaranteeing up-to-date, correct information is always accessible.

Integration with business systems: Search for a platform that may easily link with accounting, ERP, or e-commerce applications. Smooth integration lowers human effort and helps produce a consistent experience.

Flexible product attributes: The correct tool will enable you to give each product several variations – like size, color, or design – therefore simplifying management of intricate inventories.

Supplier order tracking: A strong inventory and production management software ought to follow purchase orders and delivery schedules so you can see clearly when fresh inventory will arrive.

Reorder point settings: Automatic low stock level warnings let you prevent expensive stockouts and keep regular operations. Reorder point settings help.

Cloud accessibility and security: Secure cloud access should be provided by contemporary solutions to let managers check inventory from anywhere without jeopardizing data security.

Trends & what’s new in 2025

Businesses are facing a tidal wave of innovations that are transforming their inventory management as we approach 2025. The development of the manufacturing inventory management system is no longer only about monitoring stock; it is about enabling more informed decisions, advancing sustainability, and creating supply chain resilience.

AI-driven automation

Leading among the major trends is artificial intelligence-driven automation. Companies may now forecast demand swings, automatically modify inventories, and simplify order fulfillment as artificial intelligence becomes more and more integrated in contemporary platforms. An artificial intelligence augmented manufacturing inventory management system guarantees minimum human error while maintaining optimal inventory levels over several sites.

Sustainability

Sustainability is also rising to be an important consideration. Companies are employing advanced modeling techniques within manufacturing inventory software to reduce carbon emissions, minimize waste, and optimize transportation routes. This enhances brand reputation in areas where customers appreciate environmentally friendly behavior, in addition to helping with compliance with environmental rules.

Customized solutions

Simultaneously, customized industry-specific solutions become very important. In strongly regulated industries like pharmaceuticals and healthcare, inventory systems are being customized to manage sophisticated processes, including raw material tracking, biologics manufacture, and individualized medicine, which guarantees accuracy as well as compliance.

Supply chain visibility

Another major change is the increased demand for supply chain visibility. With the rising demand for supply chain visibility, that is another significant change. Manufacturers can now monitor inventory levels in real-time at various global locations thanks to cloud-based solutions and IoT connectivity. This visibility offers executives meaningful insights to identify potential issues and make cautious data-based decisions more quickly.

Cybersecurity in operational technology (OT)

Factory environments today rely heavily on industrial control systems (ICS), sensors, and connected devices to keep production running smoothly. While these technologies bring efficiency and automation, they also create new vulnerabilities. Cyberattacks targeting OT environments have shown how quickly a breach can disrupt critical infrastructure, halt production, and even compromise public safety.

For manufacturers, investing in OT cybersecurity means deploying advanced monitoring systems, encryption protocols, and role-based access controls to safeguard sensitive data and machinery. By embedding strong cybersecurity measures into their manufacturing inventory management system, companies can ensure that their operations remain resilient against external threats, protecting both productivity and brand trust.

Integration with smart factory and Industry 4.0 ecosystem

Modern factories are no longer isolated production units. They are part of a connected network that includes Manufacturing Execution Systems (MES), Product Lifecycle Management (PLM) software, and even digital twin technology. By connecting manufacturing inventory software with these tools, businesses gain a unified view of their operations, from raw material sourcing to final product delivery.

Digital twins, for example, allow manufacturers to create virtual models of production lines, helping them test scenarios, forecast risks, and optimize performance before issues occur. Similarly, predictive maintenance powered by IoT sensors ensures that equipment failures are detected early, reducing downtime and costs. Businesses that embrace these changes early will gain a significant competitive edge in the years ahead.

Conclusion

Moreover, the function of inventory management in a manufacturing setting has changed from a supporting activity to an essential aspect of productivity and competitiveness. From its definition and advantages to its essential elements, implementation challenges, and selection, we examined in this article the significance of a manufacturing inventory management system: standards and the most recent developments in 2025.

Adopting a modern inventory management solution is not optional but rather a strategic move to maximize efficiency, lower costs, and create a more robust supply chain.

But success also depends on correct implementation, employee training, and smooth system integration, not only on selecting the ideal program.

Looking to implement a custom manufacturing inventory management system? Contact Luvina today for tailored consulting and end-to-end deployment support.

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter