For businesses wishing to stay competitive, manufacturing workflow software is now a necessity. Manufacturers need a single system that brings together every step in a production process, rather than trying to track multiple spreadsheets, paper checklists, and disconnected tools. The correct software can drive process improvements, minimize delays, and even save up to 20%.

With so many alternatives available, though, how do you determine which one best matches your company? In this article, we’ll cover manufacturing processes, essential characteristics to look out for, typical challenges, and straightforward measures to help you select the best vendor.

What is the manufacturing workflow?

A manufacturing workflow is the systematic arrangement of activities that convert an idea into a finished product. It means people, equipment, resources, and systems working in concert to ensure every step is followed correctly, efficiently, and effectively. Once again, in an industry where companies are already dealing with pressure from rising costs and competition from abroad, companies that do not have a structured process are likely to incur delays, additional costs, and may lose their competitive advantage. This is the point where manufacturing workflow software becomes crucial.

Effective workflow design paired with the correct manufacturing workflow management software lets companies simplify chores, maximize resource use, and respond more quickly to demand swings. With manufacturing workflow software, companies get the clarity and structure required to remain competitive in a more and more fluid industry.

Manufacturing workflow management software

By connecting people, machines, and processes in one platform, manufacturing workflow software ensures that production runs smoothly, errors are minimized, and efficiency is maximized. In the sections that follow, we’ll define what manufacturing workflow management software is, explore its key benefits, and look at practical use cases that show how it transforms day-to-day operations.

1. What is manufacturing workflow management software?

At its most fundamental level, manufacturing workflow management software is a digital space used to plan, automate, and monitor the entire production cycle. It does more than simple tools that only focus on task tracking or scheduling. In addition, it provides oversight of the entire process from sourcing raw materials to delivering a finished product.

By using production workflow software, producers can ensure that every job is being done in order with the appropriate resources and on time. This improves efficiency and assures product quality through bottleneck reduction.

Manufacturing workflow software, therefore, serves as the framework of contemporary factories, enabling managers to get the visibility and control needed to remain competitive in the quickly changing world.

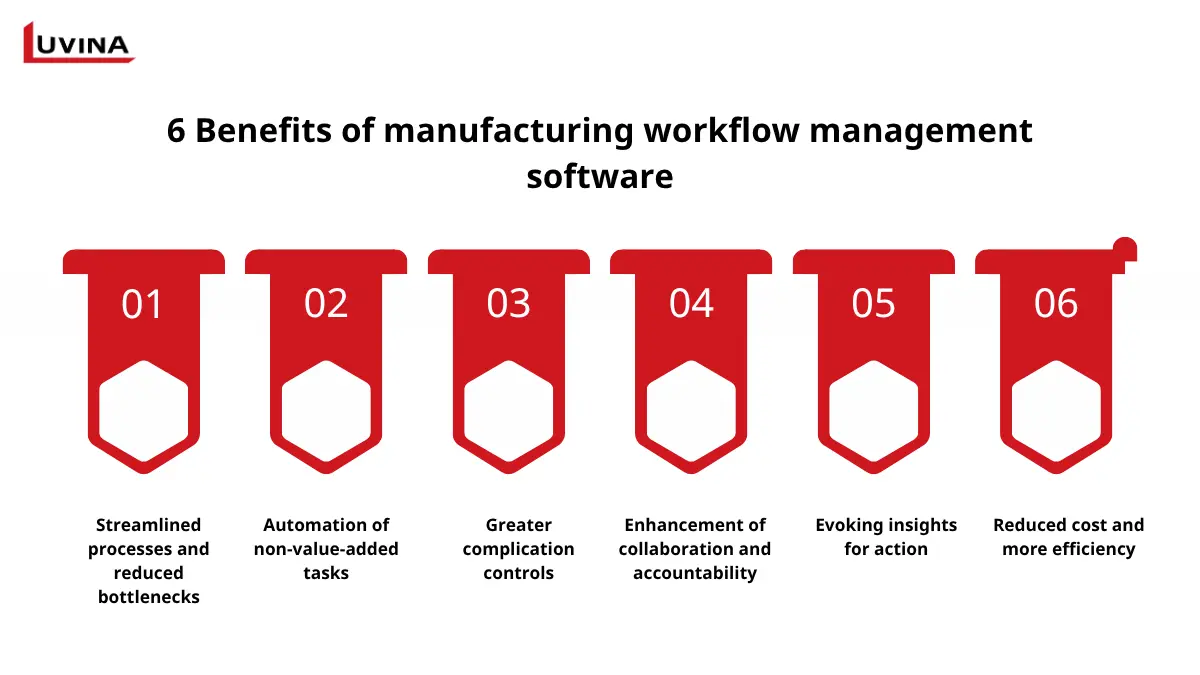

2. Benefits of manufacturing workflow management software

Manufacturing workflow software lets companies simplify processes, remove inefficiencies, and enhance decision-making at every level of production. Even in specialized industries in extremely technical settings, additive manufacturing workflow software guarantees precision and efficiency; hence, it is quite important. Below are some of the most noteworthy advantages producers may expect:

- Streamlined processes and reduced bottlenecks: By analyzing each aspect of production, companies have the ability to identify problems faster and decrease delays. This allows for a more organized flow from one department to another.

- Automation of non-value-added tasks: By removing redundancies from tasks such as clearances, work allocation, and updating status, you can free up your staff to spend their time on work that is of greater value to you.

- Greater complication controls: By monitoring processes in real-time, you can reduce mistakes and defects before they spiral out of control, thus giving you the ability to produce products to the most exacting of quality standards.

- Enhancement of collaboration and accountability: A deep knowledge of workflow can better inform the team on who is accountable for the process, which will reduce miscommunication and ambiguity and support better overall coordination.

- Evoking insights for action: Using the built-in analytics capabilities provides management the ability to again measure outputs versus other outputs based on data, develop data insights for trends, and develop improvements for processes as a result, and make decisions based on the insights from reporting.

- Reduced cost and more efficiency: Whether reducing waste or simply using fully available resources, manufacturing workflow software produces efficiency that results in lower costs and higher production.

By adopting modern workflow factory systems with the right vendor, such as Luvina, companies can transform operations. They enhance production efficiency and reduce operational costs. At the same time, they improve supply chain visibility. Most importantly, they build a scalable foundation that supports long-term growth and competitiveness.

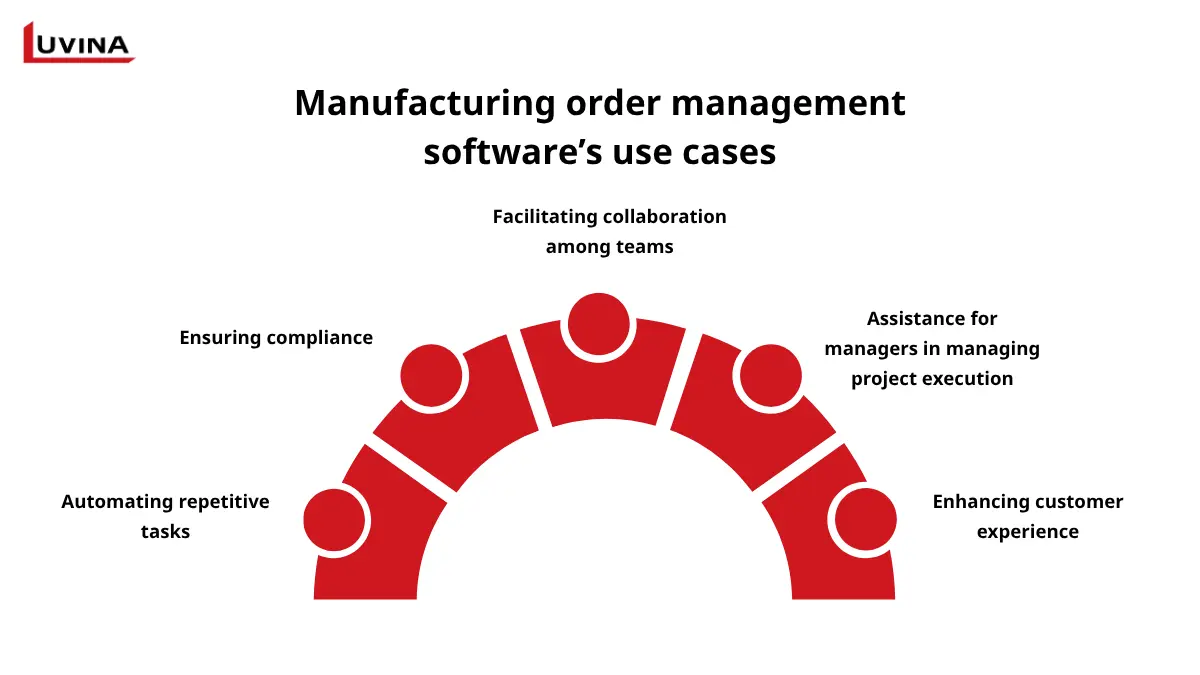

3. Practical use cases

Manufacturing workflow software guarantees the manufacturing workflow process moves along seamlessly and complies with industry norms, from cross-department cooperation to daily automation. The most potent uses companies may capitalize on are:

- Automating repetitive tasks: Fully automated solutions greatly reduce the time manufacturers spend on repetitive tasks like approvals, notifications, and data entry while also reducing human error, drivers, and timelines.

- Ensuring compliance: The software allows for strict compliance for troubleshooting and investigation through internal audits, audit trails, and reporting, minimizing the chance of substantial fines.

- Facilitating collaboration among teams: The technology embedded in your procurement, production, and quality assurance systems communicates with each other to reduce the gaps between teams and allow them to work as one team.

- Assistance for managers in managing project execution: Automated dashboards, task follow-up, and scheduling enable managers to manage projects and workers while ensuring resources are used to their best potential, and deadlines are met.

- Enhancing customer experience: Utilizing manufacturing workflow software to track orders and process returns can be beneficial for customer experience, as well as increase the speed of product delivery and improve customer experience overall.

Key features to look for in an effective manufacturing workflow management software

A strong foundation of features ensures that the workflow factory manufacturing workflow runs smoothly, while advanced capabilities can unlock even greater efficiency and adaptability. The objective is to eliminate errors, support informed decision-making, and maintain control throughout every phase of production using manufacturing workflow software. For more clarity in the assessment process, here are the main characteristics you ought to anticipate:

| Features | Why does it matter? |

|---|---|

| Easy setup and onboarding | No-code or low-code workflow creation, prebuilt templates, and an intuitive interface enable teams to launch quickly. |

| Seamless integrations | The system must connect with ERP, PLM, CRM, and other critical tools to centralize data and prevent information silos. |

| Customizable workflows | Designing procedures by department or job lets the programme adjust to your needs rather than the other way around. |

| Dynamic dashboards | Both high-level overviews and task-level details help managers track progress in real time and spot issues before they escalate. |

| Real-time reporting and analytics | Insights driven by data into delays, bottlenecks, and resource usage lead to continuous process improvements. |

Beyond the fundamentals, several companies profit from sophisticated tools that drive efficiency even further:

▪️ AI-powered automation offers predictive insights.

▪️ Auto-tagging and task smart routing improve processes over time.

▪️ Scalability: Modern manufacturing workflow software should enable challenging operations across several plants or locations without creating needless drag.

Challenges/What to Watch Out For

While workflow factory solutions bring major benefits, rollout is not without challenges. Companies most often struggle with integration, user adoption, and balancing standardization with flexibility. Addressing these challenges with practical solutions ensures smoother adoption and long-term success of manufacturing workflow management software.

| Challenges | Descriptions | Solutions |

|---|---|---|

| Integration complexity | Legacy ERP, MES, and other siloed systems make it difficult to connect with modern workflow platforms. | Adopt phased integration with APIs or middleware to reduce disruption and accelerate deployment instead of attempting full system replacement. |

| Employee resistance | Staff may push back against changes due to concerns over job security, skill gaps, or increased monitoring. | Apply structured change management, provide training programs, and establish “digital champions” to encourage adoption and build confidence. |

| Balancing standardization with flexibility | Over-standardizing workflows can limit adaptability for unique production requirements. | Create modular workflow designs that maintain core standards while allowing controlled customization for specific processes. |

| Difficulty sustaining improvements | Initial efficiency gains often fade as processes drift or organizational focus shifts. | Build governance frameworks with clear ownership, regular performance reviews, and continuous improvement cycles to sustain long-term value. |

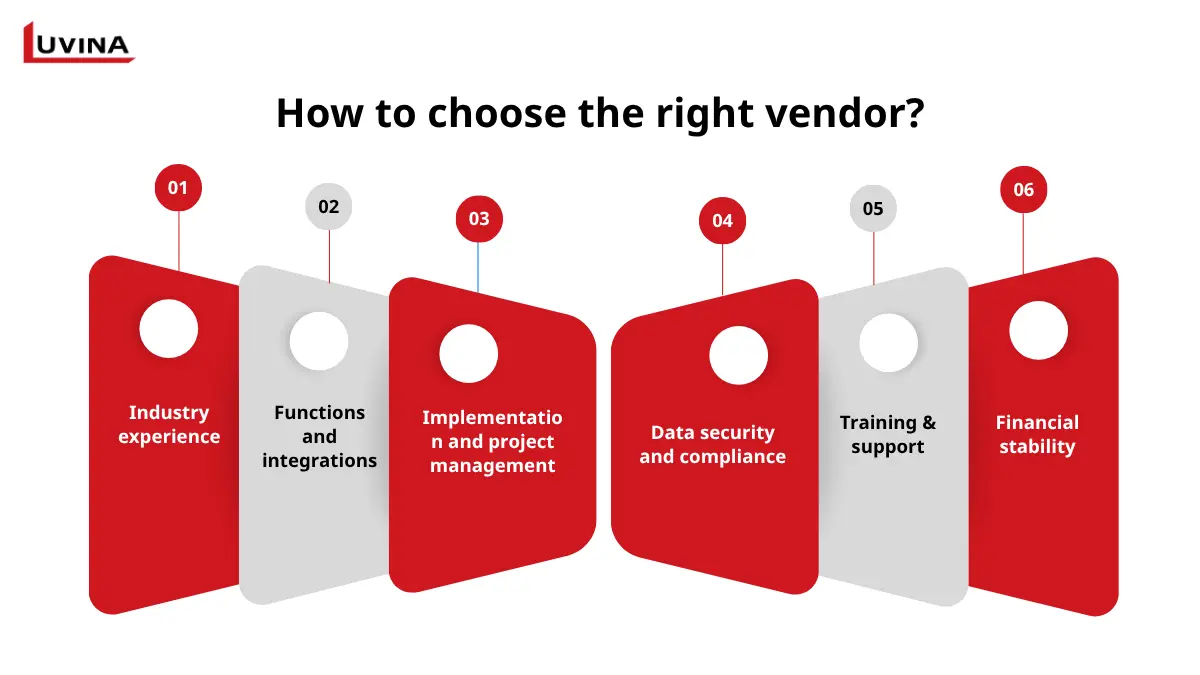

How to Choose The Right Vendor

Many businesses invest a lot in new technologies only to run into snags when the provider lacks the technological depth, industry expertise, or stability needed to enable long-term expansion. Businesses must assess prospective suppliers of manufacturing workflow management software across several important dimensions to avoid these pitfalls.

Here are some key criteria for vendor selection:

- Industry experience: Your vendors should have prior experience in your industry. Good indicators of capabilities are the years of experience the vendor has, case studies with similar companies, and knowledge of standards relevant to the industry (e.g., ISO or FDA) that your potential vendor has.

- Functions and integrations: Your provider should offer good APIs, support industry-specific protocols, be able to integrate with ERP, MES, and legacy systems, and also consider your future growth needs.

- Implementation and project management: Providers must have demonstrated experience with phased deployments, risk management, and change management, and minimize operational impact through all of this.

- Data security and compliance: Because production data and intellectual property are sensitive data, your provider must have robust data security and compliance safeguards in place. Look for a provider that has SOC 2 audits or ISO 27001 certification. Your provider should also have strong encryption in place for data in transit and at rest. The provider should also provide downloadable incident response plans.

- Training & support: Training and support are key to user “buy-in”, as well as successful operations post-implementation. Training should be role-based (operator, engineer, manager), and the vendor should provide 24/7 technical support.

- Financial stability: Along with infrastructure and technologies, the vendor’s long-term stability is just as relevant. Mature, trustworthy partners have a track record of good finances, multiple customers, and developing products.

Judged by these standards, Luvina invariably exhibits the traits of a dependable and future-ready technical partner. Having been founded and developed for more than twenty years, Luvina has gathered great knowledge in providing customized IT solutions throughout sectors, including demanding manufacturing settings.

With 750+ highly skilled IT experts, the company can create, build, and maintain end-to–end systems that satisfy both technical and business needs. Having finished over 1,000 software projects, Luvina has worked with more than 110 pleased customers worldwide.

Apart from having certifications in CMMI Level 3, ISO 9001, and ISO 27001 have excellence in the delivery of their solutions. A business that guarantees to every solution the maturity of its processes, the assurance of quality, and the security of information. These certifications show not only operational excellence but also sustained reliability toward those businesses aiming for sustained digital transformation.

Luvina is poised to help producers traverse the difficult vendor landscape and leverage its history of successful delivery, depth of technology, and strong compliance framework.

Manufacturing workflow software is best suited to their strategic purposes.

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter