Manufacturers in 2025 are no longer asking whether to digitize production. The real question is which MES software companies can deliver measurable operational value, and how to choose the right one.

Today, manufacturing execution systems (MES) play a critical role in enabling real-time production visibility, improving traceability, and connecting shop-floor operations with enterprise systems. However, the MES vendor landscape is fragmented, covering product vendors, system integrators, and custom MES development companies, each serving different needs.

This article provides:

- A clear classification of MES software companies

- A curated list of leading vendors by category

- Practical guidance to help manufacturers choose the right MES partner

Top MES Software Companies

Today’s leading MES solution companies no longer position MES as a standalone shop-floor system. Instead, they deliver platforms that support Industry 4.0 initiatives, connect quality, scheduling, and equipment performance, and enable end-to-end supply chain transparency.

The MES ecosystem now spans 3 main groups:

– MES product vendors: Companies that sell ready-made MES software.

– Custom MES development companies: Companies that build custom MES solutions for specific needs.

– MES system integrators and consulting firms: Firms that implement and integrate MES into existing systems.

In this section, we take a closer look at the top MES system integrators and consulting firms shaping the market today, highlighting what differentiates their platforms and why they are frequently selected for enterprise-level MES initiatives.

Proconex – Automation-focused MES integrator

Proconex supports MES deployment by integrating manufacturing execution systems with core process automation layers such as DCS, PLC, SCADA, and batch systems. As an Emerson Impact Partner, the company helps manufacturers ensure reliable data flow from shop-floor control systems to MES platforms, especially in regulated and process-intensive industries.

Proconex provides MES and industrial automation integration services

Compared with many MES software companies, Proconex differentiates itself through strong engineering, factory-certified teams, and hands-on field support, making it a practical choice among manufacturing execution system software vendors for enterprises that require tightly integrated, production-ready MES implementations.

MES

MES is a global service provider focused on supply chain management and custom-engineered manufacturing solutions, supporting manufacturers with complex, multi-country production networks. The company works with ISO-certified suppliers across India, China, Taiwan, Vietnam, Mexico, and North America, and integrates MES initiatives with supplier auditing, quality system development, and just-in-time delivery processes.

From an implementation standpoint, MES helps align MES platforms with real manufacturing operations such as die casting, plastic and rubber moulding, and CNC machining, while also supporting warehousing and value-added services in the US and Mexico. Compared to many MES software companies, MES differentiates itself by combining MES integration with hands-on supply chain execution, making it well-suited for automotive and durable goods manufacturers that require tight coordination between production, logistics, and delivery.

iBASEt – MES product vendor

iBASEt is a software provider specializing in digital operations for complex discrete manufacturing, with a strong focus on paperless execution and quality-driven processes. Its Digital Operations Suite brings together manufacturing execution, quality management, and MRO in a single platform, helping manufacturers gain real-time visibility while meeting strict compliance requirements such as ISO 9001 and FDA regulations – an area where many MES vendors struggle.

iBASEt enables tight integration between shop-floor operations and enterprise systems, reducing data silos across manufacturing, supplier quality, and lifecycle management. This integrated approach is one reason iBASEt is frequently mentioned among leading MES software companies, particularly in aerospace, defence, nuclear, shipbuilding, and medical device manufacturing.

Luvina – Custom MES solution provider

Luvina is a Vietnam-based IT outsourcing and software engineering company with long-standing experience in delivering end-to-end MES solutions for manufacturers. Since 2004, the company has focused on designing and deploying MES under ISO 9001 standards, with strong emphasis on system quality, data accuracy, and operational reliability.

Placed among manufacturing execution system providers in custom development, Luvina views MES as a bespoke solution matched to each plant’s production model instead of a one-size-fits-all product. The firm offers complete MES solutions, including needs analysis, system design, integration, deployment, user education, and continuous support.

Luvina is one of the most reliable MES software companies in the Asia region

While its engineering teams collaborate closely with manufacturers to link MES with current production systems and procedures, its ISO 27001-certified processes guarantee data security throughout MES integration. This model, driven by services, enables producers to simplify divided processes, see real-time production, and improve decision-making.

Luvina’s capacity to provide customized MES solutions that balance technological depth, operational fit, and long-term scalability makes it stand out among other MES software companies.

Accenture

Within the ecosystem of MES software companies, Accenture is best positioned as a MES system integrator, meaning it focuses on implementing, integrating, and scaling MES platforms rather than developing standalone MES products. As a large-scale system integrator, Accenture helps manufacturers connect MES with ERP, cloud platforms, data architectures, and cybersecurity frameworks to enable end-to-end digital manufacturing.

With deep expertise across strategy, consulting, technology, and operations, Accenture is trusted for complex, enterprise-level MES initiatives. Its core strength lies in large-scale MES deployment and systems integration, covering real-time production execution, quality management, inventory tracking, and production scheduling. This strong integration capability and global delivery footprint make Accenture a highly reputable partner for manufacturers pursuing long-term digital transformation.

Capgemini – MES implementation consultant

Offering worldwide consulting and technology services, Capgemini assists producers in strategically placing MES as a component of company-wide digital and Industry 4.0 projects. Among MES software companies, Capgemini is typically involved when MES needs to align with larger transformation aims rather than function as a stand-alone shop-floor system.

For MES projects, Capgemini emphasizes deployment and integration at scale, therefore linking shop-floor execution with ERP and other enterprise systems. Working with several MES companies, the corporation is a system integrator assisting manufacturers in automating operations and deploying MES evenly over factories.

Deloitte

Deloitte is not a standalone MES product provider but a large-scale system integrator recognized among MES software companies for its strong MES integration and advisory capabilities. Its authority in large-scale manufacturing transformation extends well beyond technology implementation. In MES-driven initiatives, Deloitte is often engaged at the earliest stages, helping manufacturers define operating models, governance frameworks, and long-term MES and MOM strategies before any system is deployed.

Deloitte supports MES implementation and integration for complex manufacturing environments

When execution begins, Deloitte operates as a high-capability MES system integrator, coordinating MES with ERP, quality, and production systems to support standardized, compliant, and data-driven operations. Its ability to combine strategic advisory, industry knowledge, and multi-vendor integration has positioned Deloitte as a trusted partner for complex, enterprise-wide MES programs, particularly in highly regulated and globally distributed manufacturing environments.

HCLTech – Enterprise MES implementation partner

HCLTech is a global IT services and consulting company with a strong footprint in large-scale industrial and manufacturing transformation programs. Operating across dozens of countries, the company has been placed among MES software companies that focus on scalability, standardization, and long-term operational impact.

Real-time monitoring, workflow automation, quality management, and performance analytics are supported by HCLTech’s MES/MOM implementation capabilities, which link shop-floor equipment with enterprise systems. HCLTech collaborates with manufacturing execution system software vendors to help companies roll out MES consistently across several locations by allowing interoperability among plants and systems.

RoviSys – Vendor-neutral MES & automation integrator

Originally founded in 1989, RoviSys is an independent integration and process automation specialist distinguished by its vendor-neutral attitude. The company aims to provide producers with technological selection freedom by combining MES with automation and control systems without being bound to proprietary platforms. For companies with complicated, technology-diverse manufacturing environments, RoviSys has become a valued ally among MES software companies thanks to this approach.

As one of the best MES companies, in MES and MOM projects, RoviSys delivers implementation and integration services that support real-time data collection, production tracking, inventory management, and performance analysis. Its solutions connect MES with ERP and control systems to improve scheduling, quality management, and workflow optimization.

Radixweb – Custom MES developer

With more than 2 decades in custom software development and outsourcing, Radixweb works with manufacturers that need MES built around real operational constraints, not predefined templates. The company’s strength lies in translating business requirements into flexible execution systems, a capability that has become increasingly important as MES software companies move away from one-size-fits-all platforms.

Rather than positioning itself as a pure MES vendor, Radixweb approaches MES as part of a broader digital ecosystem, supporting system design, integration, and long-term evolution. This project-based, agile delivery model allows manufacturers to adapt execution systems as operations scale or change – something many companies struggle to support once initial deployment is complete.

How to Choose the Right MES Vendor

MES software companies are vital in determining how well production, quality, and supply chain processes interact as manufacturing environments become more linked and data-driven. As your company changes, the correct partner will enable you real-time presence on the shop floor while assisting with scalability, adaptability, and ongoing development.

| Vendor types | Description | Best for |

| MES product vendors | Sell ready-made MES software | Standard MES needs, quick deployment |

| Custom MES development companies | Build MES tailored to specific requirements | Highly customized manufacturing |

| MES system integrators & consulting firms | Implement and integrate MES with existing systems | Large-scale, complex MES programs |

Which vendor types is best for your organization

On the other hand, manufacturers evaluating MES suppliers should bear these main requirements in mind:

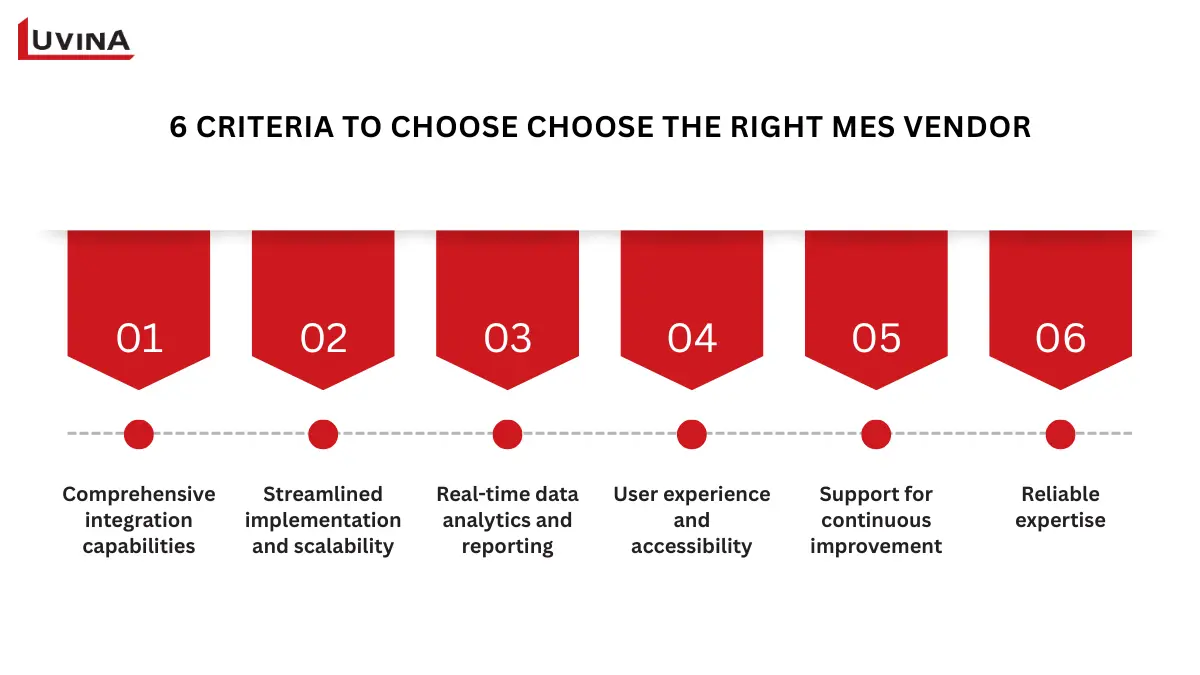

To choose the right mes companies, don’t overlook these criteria

Comprehensive integration capabilities

A current MES must fit smoothly with already in use company systems like ERP, PLM, and automation solutions. Leading MES software companies usually give open APIs and adaptable integration frameworks so that producers may link existing systems while being ready for future technologies.

Streamlined implementation and scalability

Long-term MES implementations may slow value realization and disturb operations. Rather than inflexible, long-running initiatives, producers should give vendors concentrating on quick configuration and phased implementation priority. Scalable architectures also matter.

Implementation speed and capacity to expand with operational complexity should be considered as central decision criteria when assessing MES software companies.

Real-time data analytics and reporting

An efficient MES should have integrated reporting and dashboard features together with ordered, easy data. Just as crucial is the capacity to export or link information to external analytic tools without extensive modification. Companies that give data access first allow manufacturers to convert execution data into practical insights instead of static reports.

User experience and accessibility

Many companies today stress simple navigation and enable safe remote access via user-friendly, cloud-based interfaces. A user-friendly MES lets teams interact more regularly with the system, therefore raising operating responsiveness and data accuracy.

Support for continuous improvement

Manufacturers may always improve processes and product quality without significant system changes, thanks to agile thinking vendors’ MES design.

Reliable expertise

Domain knowledge and vendor assistance define long-run success. Rarely do MES projects stop at go-live; inquiries, changes, and optimization attempts are unavoidable. Strong MES software companies offer well-informed support teams with manufacturing experience, guaranteeing quicker problem resolution and more pertinent advice over the lifecycle of the system.

Source: https://www.gartner.com/reviews/market/mes-mom-implementation-providers

Common Challenges When Working With MES Vendors

Implementing MES often exposes manufacturers to repeated problems that directly affect schedule, expenses, and system performance. These difficulties usually come from inconsistencies between corporate expectations, technical implementation, and long-term usability when partnering with MES vendors and assessing several MES software companies.

| Challenge | Description | Best practices |

| Misaligned expectations | Business goals are not clearly translated into functional scope, causing solutions delivered by vendors to meet technical specs but miss operational value. | – Define clear objectives and KPIs upfront- Validate use cases before implementation |

| Limited industry expertise | The vendor may lack knowledge of specific sectors, leading to inefficient solutions. | – Choose MES software partner with proven industry experience- Review relevant case studies |

| Complex system integration | Integrating MES with ERP, SCADA, or PLCs can be tricky and error-prone. | – Assess integration architecture early- Use standardized connectors and APIs |

| Weak project governance | Multiple stakeholders can slow down decisions and blur responsibilities. | – Assign a single project owner- Establish clear governance and escalation paths |

| Poor change management | Employees may resist new MES systems, reducing ROI. | – Include change management in scope- Deliver role-based training |

| Limited post-go-live support | Lack of long-term support and scalability planning reduces ROI as production evolves, a common risk when selecting mes software companies focused only on deployment. | – Evaluate SLAs and support models- Review product roadmap and scalability |

Challenges and solutions when working with MES vendors

Source: https://www.criticalmanufacturing.com/blog/all-you-need-to-know-about-mes-implementation-providers/

MES Market Trends Shaping Vendor Selection

While characteristics including AI-assisted quality inspections, predictive scheduling, digital twins, and plant-wide data gathering are becoming commonplace, contemporary MES software today effortlessly interacts with ERP, PLM, SCADA, and IIoT systems. To enable producers to maximize output and quality, MES software companies are concentrating on providing these sophisticated features.

The market will keep highlighting artificial intelligence, machine learning, and real-time analytics in the future. Mergers and acquisitions among mid-tier manufacturing execution system software vendors will combine knowledge and broaden worldwide reach. Important distinguishing characteristics are emerging for cloud-native solutions, robust cybersecurity, and value-based pricing systems, therefore directing manufacturers toward scalable, flexible, and creative MES installations.

Source: https://www.firstresonance.io/blog/best-mes-software-vendors

Conclusion

Choosing the right MES software company is not about selecting the most popular vendor. It is about aligning technology, operations, and long-term strategy.

By understanding vendor types, evaluating real-world capabilities, and prioritizing integration and scalability, manufacturers can deploy MES as a sustainable foundation for digital manufacturing success.

If you would like to explore how custom MES solutions can be tailored to your production environment, Luvina can support you with practical guidance and implementation expertise.

Resources

- https://tech-stack.com/our-services/best-mes-software-development-companies-for-manufacturers-in-2025

- https://www.firstresonance.io/blog/best-mes-software-vendors

- https://www.criticalmanufacturing.com/blog/all-you-need-to-know-about-mes-implementation-providers/

- https://www.gartner.com/reviews/market/mes-mom-implementation-providers

- https://ensun.io/search/manufacturing-execution-system-mes/united-states

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter