BOM & Document Management with ARAS Innovator

Highlight

End-to-end software development

Aras Innovator: Programming languages: VB.NET, C#, JavaScript

Low-Code

Database: SQL Server

Luvina partnered with Japan’s leading SI companies to support top manufacturers in automotive, electronics, and energy. The project focused on solving issues in material tracking, document management, and machinery maintenance. Using Aras Innovator, Luvina customized features for BOM, document, and asset management. These solutions reduced material mix-ups, improved version control, and increased operational efficiency.

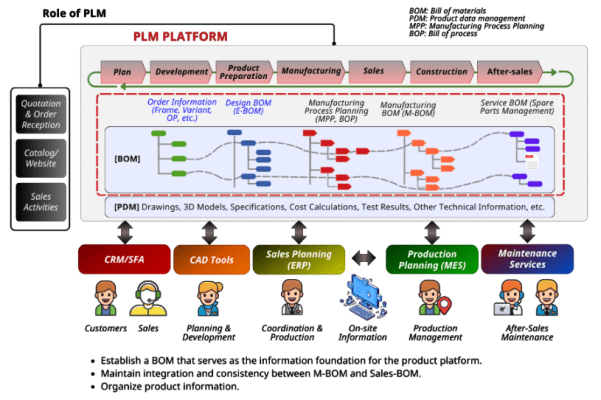

[Aras Innovator] Aras Solution Covers the Entire Product Lifecycle

- Customized document management functionality on Aras Innovator for enterprises

- Customized BOM management functionality on Aras Innovator for manufacturing companies

- Developed a new machinery and equipment management system based on the Aras Innovator platform for enterprises

- Developed information and document management functions for factory locations, highways, substations, etc., on the map using ARAS

ABOUT CLIENT:

The end-user customers are companies and enterprises involved in the manufacturing of automobiles and motorcycles, computers, and energy. These companies sought solutions for document management, BOM management, and enterprise resource management. They decided to collaborate with the largest and most trusted Japanese SI companies in the industry, as our direct client.

INDUSTRY: Manufacturing

DURATION: 05/2022 ~ Now

SIZE: 14.3 MM

SERVICES:

- Technical consulting and requirement definition

- POC development

- Design

- Development, testing, and release

- Maintenance and operations

KEY TECHNOLOGIES:

- Aras Innovator: Programming languages: VB.NET, C#, JavaScript

- Low-Code

- Database: SQL Server

- Material management: The customers faced issues with material mix-ups during the production process.

-

Document management: The customers also struggled with document management, version control, and access rights management.

-

Machinery management: The customers experienced difficulties in managing their machinery, including issues like equipment failure and maintenance.

-

Data lifecycle management: The end users lacked a lifecycle management system for data within their factories, substations, highways, etc., making it challenging to manage documents and operations within the organization.

- Develop a feature to compare differences between actual materials and planned materials before production.

- Customize the document management functionality to resolve all the issues that the client encounters.

- Develop a POC for functions related to machinery management within the factory.

- Need a solution for managing information and documents at all branches and creating a comprehensive map storing information for all clients’ facilities.Utilize Aras Innovator technology to develop or customize features that address and manage the customer’s challenges.

- Utilize Aras Innovator technology to develop or customize features that address and manage the customer’s challenges.

Download for more details.

- IMPROVED DOCUMENT MANAGEMENT:

- Accurate version control and document management.

- Documents are securely managed with access rights tailored to user needs.

- TIME SAVINGS IN DOCUMENT MANAGEMENT:

- Streamlined document management across power plants.

- Clear visualization on maps makes it easy to identify locations and manage overall operations.

- REDUCTION IN MATERIAL MISUSE:

- Significant decrease in material mix-ups during production.

- EFFICIENT MACHINERY MANAGEMENT:

- Quick and effective management of machinery information within factories.

What our clients said:

“We are incredibly grateful for the high level of technical support we’ve received in each project. Please continue to assist us in expanding our Aras business, and let’s work together to achieve further growth.”

“Thank you for your assistance with Project Na*. Although the requirements were still vague, Heartcore-Luvina thoroughly reviewed them, provided feedback on the problematic areas, and suggested fixes. Heartcore-Luvina also conducted QA on the screen operations and proposed improvements. I find Heartcore-Luvina’s processing speed to be quite fast, even faster than other patterns in Japan. I have high expectations for Heartcore-Luvina. Please continue to support us!”

“Thank you for your support on Project H*. Your extensive technical knowledge was invaluable, from creating MAC policies to modifying Excel tools.”

Read More From Us?

Sign up for our newsletter