Statistics have shown that the inventory management software market is expected to reach $2,998.55 million by 2028, with an annual growth rate of 11.9%. These numbers, along with many other statistics, clearly reflect how technology can influence the development of simple supply chain management software.

To avoid falling behind, investing in inventory management software development is a wise decision in today’s fast-paced consumer world. If you’re looking to develop an inventory management system, keep reading. We’ll provide you with essential information on why and how to do it.

What is Inventory Management Software?

Inventory management software is a tool for tracking every movement of your inventory while it makes its entry and exit in a company. Well-managed inventory software keeps you up-to-date, providing real-time information about what you have in stock, where exactly in the warehouse, how much is available for sale, and how long time it has been in storage.

This information helps businesses eliminate the risks of overstocking and avoid stockouts that could significantly disrupt the sales cycle and impact the company’s profits. In short, inventory management software covers almost everything from production and warehousing to logistics and retail management.

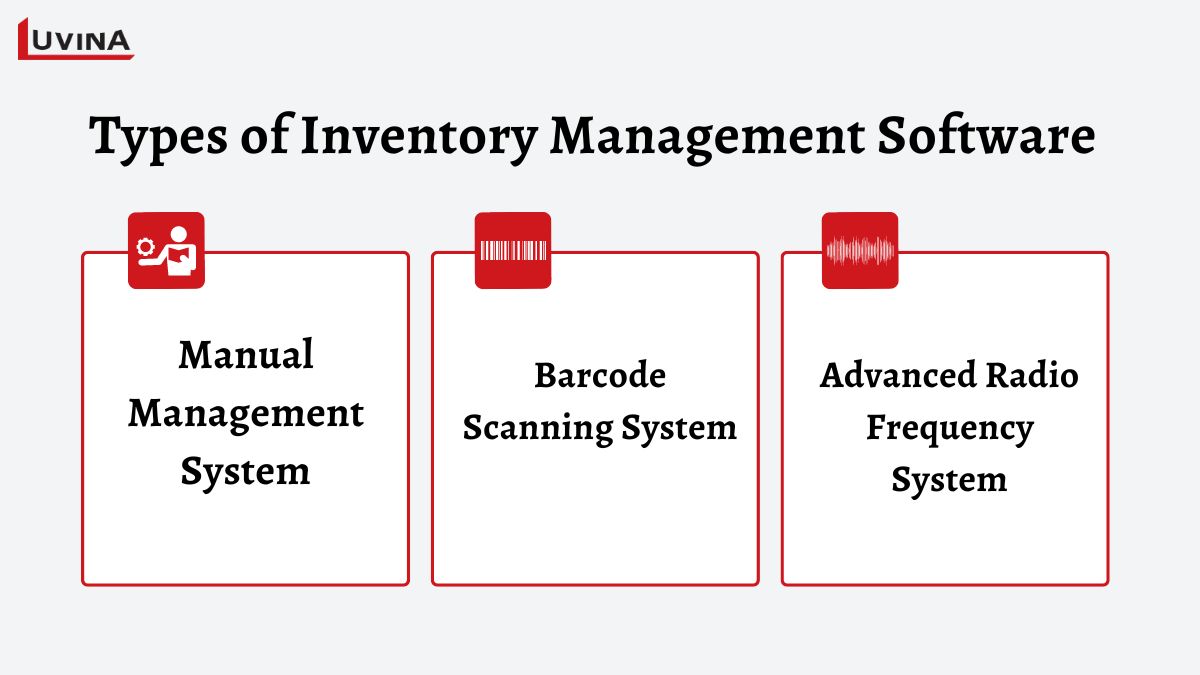

Types of Inventory Management Software

There are several ways to classify inventory management software. However, the most common method is based on the software’s purpose and core features. Before proceeding with inventory management software development, it’s essential to understand some of the classifications of these systems

1. Manual Management System

In a manual management system, even the most complex of calculations are done through formulas that the user has manually set. Such inventory management software would find applications in small-scale startups and small businesses that deal in and manage their inventory on paper. The major setback when you develop an inventory management system of this type is that errors may occur with much ease during management since everything is handled manually.

2. Barcode Scanning System

This system is stronger compared to the manual system because it gives a business the facility to track hundreds of items and extract data directly from a point-of-sale system. The moment goods reach the warehouse, this system gets updated automatically; hence, the inventory managers can view and update the inventory. Transfer of goods from one warehouse to another, from suppliers to the warehouse, and from the warehouse to customers is easier with the use of barcode technology.

3. Advanced Radio Frequency System

RFID technology is considered even more highly regarded than barcode scanning systems. Large companies typically utilize the system to track the thousands of items inside and outside the corporation daily. The technology behind this system can be divided into two types: active and passive technology.

Active technology has a range of 300 feet and uses fixed card readers to track the movement of an item throughout the warehouse. The movement is recorded every time the item passes a card reader installed in the warehouse, enabling real-time inventory tracking. Passive technology, with a range of 40 feet, uses handheld card readers to track the movement of items. These technologies make it easier to transfer inventory between warehouses.

Key Features of Inventory Management System

When you discuss with an inventory management software development company, the first thing the specialists will ask you is what you want to include in your software and what you expect from it. You might want to incorporate many features into the system, but selecting the most essential ones will help you save both cost and time during inventory management software development. In the following section, we’ll highlight some key features that we believe you should consider when developing an inventory management system.

| No. | Feature | Function |

| 1 | Reorder Point | The product list along with the necessary quantities to be kept in stock will be programmed into the software to notify the manager about the need to reorder products, helping to prevent stock shortages or overstock situations. |

| 2 | Product List | Organize and arrange inventory with details such as price, stock status, SKU, etc. |

| 3 | Asset Tracking | Adding asset tracking features during inventory management software development will help you track products in the warehouse or store through barcodes, radio frequency identification, serial numbers, or lot tracking numbers. |

| 4 | Reports | Reporting tools help businesses build seamless workflows, providing information such as which products need reordering and which products are profitable. |

| 5 | Barcode Scanning | To develop a warehouse management system, you should not overlook the barcode scanning feature. This feature helps track products through their barcodes, eliminating the need for expensive hardware. |

| 6 | Accounting Tools | Accounting tools will provide accurate inventory valuation. You just need to enter detailed information, without spending hours manually writing it out. |

| 7 | Raw Material Tracking | Helps determine if there is enough raw material to carry out new tasks in the production process, control labor costs, and direct the workforce to more effective solutions. |

| 8 | Finished Goods and Parts Inventory | Adding this feature in inventory software development helps track finished goods available in the warehouse or store for immediate shipment to customers. Additionally, this feature helps monitor the availability of parts if customers want to order a custom product. |

| 9 | Automatic Reordering | Purchase orders will be automatically created when inventory reaches minimum levels, making it easier to manage stock levels. |

| 10 | Integration with Maintenance or ERP Software | You can integrate your inventory management software with ERP or any other maintenance software to avoid re-entering data into multiple programs, saving time. |

| 11 | Multi-location Support | Manage and track multiple warehouses and stores to keep track of the company’s total available inventory. |

| 12 | Bin and Shelf Tracking | Provides the exact location of a specific product within the warehouse. |

| 13 | Picking | This is a feature you need to add during inventory system development. It helps you collect all items according to the quantities listed before shipping them in line with customer orders. |

| 14 | Real-time Inventory Tracking | Track inventory in real-time across multiple warehouses and stores. |

| 15 | Expiration Date Recording | Assign expiration dates to keep track of the shelf life of these items. |

| 16 | Series Tracking | Helps manage hundreds of thousands of serial numbers in the system. |

| 17 | Images | Allows assigning multiple images to an item or setting a default image that will appear for the item. |

| 18 | Pricing | When you develop an inventory management system, the pricing feature allows you to set various price levels for items so you can quote any price you want to customers. |

| 19 | Logistics Management | Integrates with logistics management software to transparently handle the movement of goods and materials, helping warehouse managers easily track locations and timing. |

Benefits of Inventory Management Software Development

Inventory management software development will help you build an inventory management system and standardize your workflow. Here are some reasons why you should develop such software:

- Centralized storage tools: When you develop an inventory management system, you can track the status of all different products and inform customers about their shipment status.

- Better organization of warehouse operations: Monitoring all products in the warehouse helps you save time and effort as you no longer need to visit the warehouse to check the status of any product when needed.

- Increased sales productivity: When you develop inventory management software, you can track all warehouses, reduce customer loss, and minimize common reporting errors found in manual inventory management. Additionally, the inventory management system will help you meet delivery deadlines, so customers won’t have to wait long for their orders and can easily track their goods and know the exact arrival date.

- Better order frequency adjustment: Once you develop a good inventory management system, you can monitor actual inventory levels and reorder whenever necessary, avoiding product waste and financial loss.

- Increased customer satisfaction: Your customers will be more satisfied with accurate feedback, timely delivery, and appropriate services.

- Accurate forecasting and detailed planning: Managing inventory levels will help you plan better for the future. Additionally, most inventory management tools provide analyses to assess trends and opportunities, as well as measure sales and productivity.

How to Develop Inventory Management Software?

Inventory management software development is a way to enhance production and retail business operations. This development process typically involves several stages:

- Identify Needs: Determine the company’s requirements for inventory software development.

- Analyze Requirements: List detailed requirements, conduct market research, and assess feasibility.

- Design and Framework: Prepare prototypes before finalizing the system design.

- Development: Begin developing an inventory management system. Developers and designers will handle coding and product design.

- Testing: Before widespread use, the software needs detailed testing. This testing will be conducted manually by quality control experts. After testing, quality control specialists will provide feedback to developers to fix any remaining issues and ensure a high-quality warehouse management system.

- Widespread Deployment: The tested software will be deployed to servers.

- Maintenance: Perform regular updates as well as timely maintenance and support.

Latest Technology Trends Integrated with Inventory Management Software

In the year 2024 and beyond, it is expected that inventory management software development shall again take center stage in driving efficiency and cost reduction, streamlining supply chains and distribution networks. For years now, the sector has been the most automated in business operations. Some giants, like Amazon, use robots even in handling goods.

One of the technological trends enhancing inventory software development is Artificial Intelligence. AI has been able to help retailers increase their revenue by 6 to 10% through personalization. AI let the retailers predict demand, reduce waste by calculating the actual amount of raw material needed, automate logistics, perform updates on the inventory, and so on. Overall, the introduction of AI in inventory system development has not only made the whole process more accurate but also made managing schedules and work patterns in this field easier.

Besides AI, other trends expected to grow significantly in inventory management software development include:

- Data Analytics: Data analytics will provide insight into the customer’s behavior and purchasing patterns, which will revolutionize how inventory is managed.

- Integration with the Internet of Things (IoT): IoT devices, such as RFID tags, sensors, beacons, etc., will help track inventory across the entire supply chain. Devices monitor variables including temperature, humidity, expiration dates, and movement to trace products with accuracy- to inform decisions concerning maintenance, inventory shortages, and proper storage conditions.

- Cloud-based inventory management will also remain one of the most key technological trends for the forthcoming years. With cloud access from anywhere in the world, on any device connected to the internet, real-time inventory control can be boosted and business can be smoothly operated with informed decisions.

IT Cost to Develop an Inventory Management System

The cost of inventory management software development will depend on the number and type of features your business wants to integrate into the inventory management software. You must gain a clear understanding of what your business needs and what you expect the system to perform before you consult an inventory management software development company. The better you can understand your needs, the easier it will be to set a realistic budget.

Currently, custom inventory management software development in India is one of the favorite choices among various businesses due to the much-reduced development cost of an inventory management system against other countries. In addition, you can refer to the development cost in different geographic regions below.

- – Developers based in the United States: $50 to $250 per hour.

- – Developers in Eastern Europe: $30 to $150 per hour.

- – Developers in India: $10 to $80 per hour.

Besides India, Vietnam is also one of the desired places for companies seeking inventory automation facilities. By knowing that a developer costs from $20 to $45 per hour, cooperation with a company developing an inventory management system and based in Vietnam will save a company a significant sum of money.

How to Choose the Right Inventory Management Software Development Company

In developing your inventory management software, you should consider many factors that will ensure you get the best company fitted for your business. Here are the most important factors that will be considered:

- Experience and Expertise: Company experience in your industry will assure greater success, along with expertise in developing inventory management systems for your very specific needs.

- Portfolio and Case Studies: Check their previous projects and case studies to ensure they have handled projects like your project successfully and provided quality solutions.

- Development Process: Make sure the development methodology of the company fits your project needs: Agile, Waterfall, or other approaches.

- Cost and Budget: Find a balance between cost and quality, ensuring that the solution gives good value for the money that has been invested.

- Scalability: Ensure the software is scalable and can grow with your business in the future with changing technologies.

- Client Reviews: Go through the reviews and speak to previous clients to determine overall satisfaction and dependability for your decision-making process.

- Cultural Fit: Also, consider the work culture of the company, the way they communicate, and what challenges are likely to arise since most of them will be from other countries.

- Legal and Security: Verify that you retain full ownership of the software and that the company has stringent measures for data security.

By now, you likely understand why developing an inventory management system is a top choice for many businesses. If you haven’t integrated such a system into your operations, now is the time.

Looking to develop an inventory management system? Luvina is a partner you shouldn’t overlook. In today’s digital age, digital transformation is revolutionizing the logistics and transportation industry, enhancing operational efficiency, speeding up decision-making, and improving information sharing. However, this also brings challenges such as security risks, supply chain disruptions, and difficulties adapting to new technologies. As a professional logistic software development company, Luvina is ready to support businesses in their digital transformation journey. We are committed to helping our clients tackle these challenges and enabling businesses to leverage the benefits of technology.

Since 2004, Luvina has completed numerous projects, including new developments, testing, software maintenance, and upgrades for various logistics and transportation companies, ensuring customer satisfaction. Among our offerings, inventory management software development helps businesses build an efficient supply chain foundation, ensuring organized control and optimal inventory management. Luvina is here to support your inventory software development needs and help your business thrive.

Contact Luvina today to receive innovative solutions tailored to your specific needs.

Related Posts:

Read More From Us?

Sign up for our newsletter

Read More From Us?

Sign up for our newsletter